Engineering the Future: The Hybrid Stator Redefining Electric Motors

- Horizon Technology

- 03.06.2025

- Lamination Steel

The electric motor industry is undergoing a quiet revolution, driving a relentless push for energy-efficient electric motors with compact, high-performance designs. One ...

READ MORE

Sintered Soft Magnetics—Customized Design for DC Applications

- Horizon Technology

- 10.03.2024

- Sintered Soft Magnetics

Powder Metallurgy, Then and Now The Metal Powder Industries Federation recently republished an interesting article about the early history of powder metallurgy (PM) that ...

READ MORE

SMC – Enabling New Motor Designs for a Circular Economy

- Horizon Technology

- 09.11.2024

- motors

Engineers who are tasked with designing and specifying electric motors for new and updated applications are now facing three interdependent challenges: optimizing ...

READ MORE

How SMCs Can Fuel Innovation in Power Tools

- Fran Hanejko

- 08.29.2024

- Applications

History of Power Tools Until after World War II, the US power tool market was largely focused on the industrial metal working and wood working industries. The home and ...

READ MORE

Can Electric Wheel Hub Motors Be More Efficient?

- Horizon Technology

- 07.09.2024

- Soft Magnetic Composite

The move to electric mobility is well past passenger cars.

READ MORE

Trend in Electric Motors for HVAC

- Horizon Technology

- 06.19.2024

- motors

In 2012, the total energy consumption of the United States was estimated to be 96 quadrillion BTUs (96 x 10^15). Figure 1 illustrates how this usage breaks down by ...

READ MORE

Shaping the Future: Navigating the Horizon of Powder Metallurgy's ...

In the intricate array of modern manufacturing, the Powder Metallurgy (PM) industry stands as a dynamic force, continually shaping the future as a sustainable metal ...

READ MORE

Unleashing the Potential of Sintered Soft Magnetic Materials in ...

Unlocking the Potential of DC Motors and Solenoids Did you know that the average American vehicle is packed with more than 60 DC motors and solenoids? As we shift ...

READ MORE

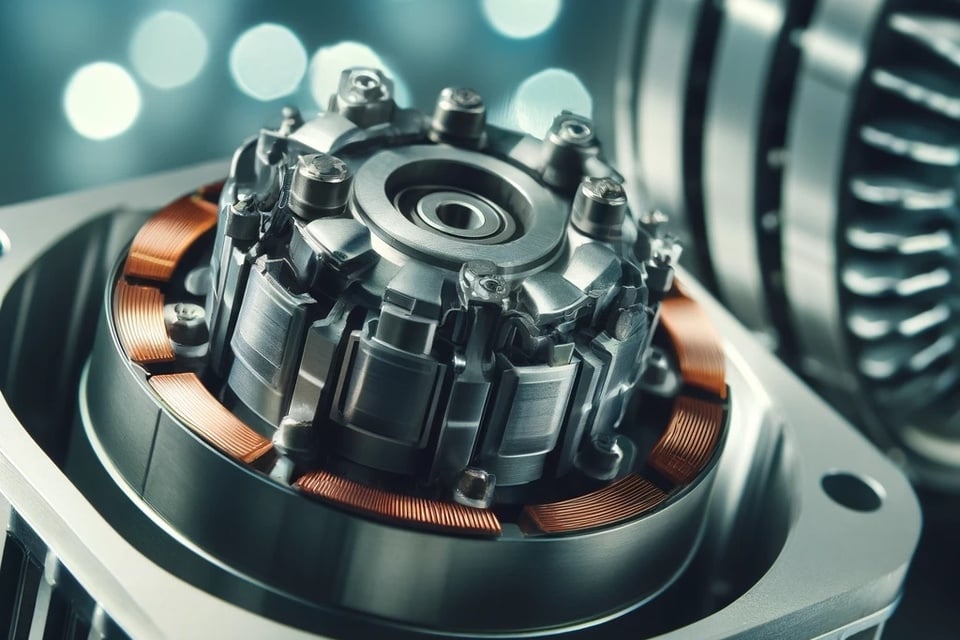

How Advanced PM can Benefit Electric Motors

Powder Metallurgy (PM) has established itself as a leading-edge parts manufacturing process - enabling new designs with simplified production while simultaneously ...

READ MORE

SMC & Powder Metallurgy - Ultimate Design Freedom

PM – A Reliable Part making Technology Today’s manufacturing environment demands flexibility of design along with minimum energy consumption and long-term reliability. ...

READ MORE

Recent Posts

Get Updates via Email

ISO 9001:2015

We’re proudly ISO 9001:2015 certified, which means quality assurance at every stage of your project.

Our internal systems have been inspected for reliability and cost effectiveness, and received the seal of approval.

View our ISO 9001:2015 certification.

Plex Systems

Horizon uses Plex Manufacturing Cloud software to meet your strict and exhaustive traceability and quality goals.

Plex's real-time updates let us continuously improve efficiency and customer responsiveness. Your lead times will decrease, and you’ll receive quicker service.

.jpg)

.jpg)