unprecedented soft magnetic applications |

< 5% porosity (industry average: 12%) |

joining of dissimilar materials |

Customers of our powder metallurgy services fall into two groups. Does your die cast component need upgrading? We may have the technology to redesign that for powder metallurgy and cut costs. Are you already using sintered metal parts manufacturing but want to take your electric machine component to another level? We can facilitate 3D design and unmatched magnetic performance.

Horizon’s services and capabilities translate to many types of applications -- not just the auto industry!

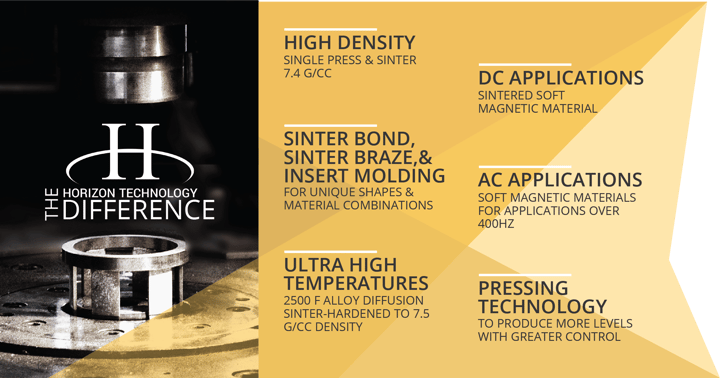

Here are the services and capabilities we offer to help you achieve your goals ...

We are proudly ISO 9001:2015 certified. Any outside vendors we use must also meet the same process standards.

Whether this is your first time taking advantage of powder metallurgy or your 100th, we have something unique to offer your design.

Our experienced engineering team will point out potential design-for-manufacturing and tolerance issues

Materials development is customized for each project. We create unique alloys for:

We rely almost entirely on advanced, unique materials. Why do we go out of our way to find you a one-of-a-kind mix?

Our powder metal materials include, but are not limited to:

Our powder metallurgy process is customized to each project. Our sintering and high-temperature sintering capabilities surpass just about anything you’ll find in North America.

Your product is manufactured with highly accurate controls and continuous process monitoring. That means fewer wasted runs, more product per material volume, and tighter tolerances.

Automated inspection is an added layer of protection for the customer. We recognize the need in certain applications for 100% inspection for critical dimensions and features.

Horizon has developed several trusted partnerships over the years, all in the name of making your supply chain more convenient. Keeping your manufacturing needs under a single umbrella ensures reliability and consolidated lead times.

Horizon Technology clears the path for you to innovate. Our advanced materials systems achieve the highest mechanical, magnetic, and density properties possible with power metal.

Horizon-produced powder metal components are known for blazing new trails in the industry. Check out these three proven, real-world examples:

Check out some of our other resources!

We’re proudly ISO 9001:2015 certified, which means quality assurance at every stage of your project.

Our internal systems have been inspected for reliability and cost effectiveness, and received the seal of approval.

Click here to view our ISO 9001:2015 certification.

Horizon uses Plex Manufacturing Cloud software to meet your strict and exhaustive traceability and quality goals.

Plex's real-time updates let us continuously improve efficiency and customer responsiveness. Your lead times will decrease, and you’ll receive quicker service.

Sintered Metal Fulcrum for Auto Motor

Small Stater for Electric Motor, Soft Magnetic Composite

Automotive Brazing Application

People. Passion. Powdered Metal.

293 Battery Street

St. Marys, PA 15857

(814) 834-4004