Electric motor design is about more than just reducing cost -- it’s about the chance to get innovative and exceed performance expectations.

If you’re already experimenting with new electric motor solutions that are a little "different,” consider incorporating powder metallurgy (PM) into your plan. Whether you’re looking for electric motor efficiency or cost reduction, chances are a PM solution exists.

Use this hub as a resource for understanding the advantages of powder metallurgy for motor applications vs. competing technologies like electrical steel laminations. Below you can learn more about the untapped potential powder metallurgy holds for motor makers -- and how you can use it to push the boundaries of your design.

Using powder metal parts to cut costs is nothing new. Using powder metal components to further the “electrification” of transportation and other electromagnetic applications is the new frontier for driving performance and cost-efficiency to new heights.

In the case of transportation, these opportunities go far beyond the traditional automobile. Powder metallurgy processes and materials are seeing more use in:

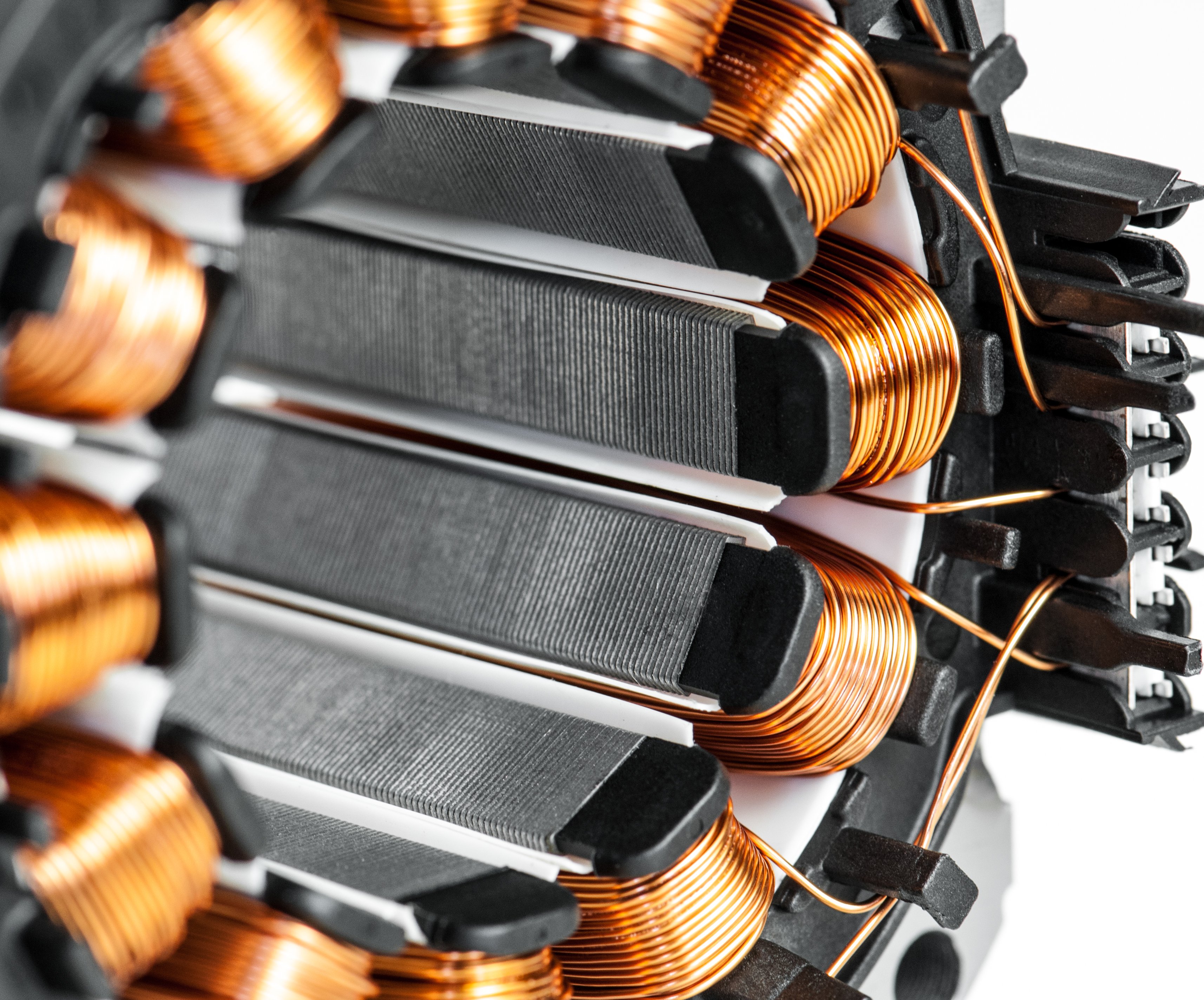

Powder metal materials and processes can optimize both AC and DC motors -- everything from axial flux motors to magnetic torque tunnels. Basically, anything that needs to be small and efficient needs to include metal powder parts.

Resource: 3 Trends in Manufacturing Auto Parts: Does Powder Metal Have a Place?

A powder metal part is born when premixed iron alloy is pressed into a desired shape to produce 3D structures. Because it’s a material-efficient, net-shape process, it’s dramatically easier and more efficient to design with powder metal vs. machining or another subtractive process.

Think about how engineers place electric car motors on the front or rear axle -- space is at a premium. Today it’s possible to redesign the motor with powdered metal components to use space more efficiently. You can use the extra space to include other components or just make the entire product smaller and lighter!

Advanced powder metallurgy manufacturers are here to help e-motor designers meet the increasing demand for smaller electric and hybrid motors.

Resource: Electric Motor Efficiency & 4 Other Uses for Soft Magnetic Composite

Manufacturers are committing to further optimizing electric drive components to reduce weight in e-vehicles.

A smaller motor is naturally lighter. Using fewer and smaller components is where powder metal shines.

Resource: A Groundbreaking Rotor Material

Developments in ultra-high-temperature sintering coupled with advanced materials can create solenoids and relays used in actuators that need more rapid response times.

Additionally, rotors used in brushless DC motors can achieve high magnetic performance when you use sintered soft magnetic powders.

Resource: What Is Sintered Soft Magnetic Material?

Soft magnetic materials are the perfect match for motors and stators. They possess competitive magnetic properties, but with higher electrical resistivity.

Use one of the many unique grades of soft magnetic composite as your new electric motor material to attain the highest frequencies possible.

Cutting costs for a growing variety of pressed and sintered motor components remains the heart of powder metallurgy.

If your current design is cumbersome and producing excessive scrap, consider a redesign with powder metal. PM produces a more compact design with virtually no leftover material -- scrap waste rarely exceeds 3%.

Sometimes powder metallurgy can even reduce the number of parts needed in an assembly traditionally made with electrical lamination steel.

Resource: Soft Magnetic Composites: A Visual Crash Course on Improving Motor Efficiency

In the race to innovate, electric motor designers no longer need a “good enough” solution, they need a great solution. Powder metallurgy’s benefits go hand in hand with cutting-edge design.

How can Horizon help you brainstorm a solution? Share your design challenges via the form, and an expert engineer will get back to you shortly.

Fran Hanejko is an industry-leading expert who works with Horizon as our Senior Advanced Materials Engineer. Fran has decades of experience in powder metallurgy, including managing customer applications for a world-leading raw material supplier. He graduated from Drexel University in 1974 with a master’s degree in materials engineering.

Contact Fran with your materials questions by filling out the form on this page.

Most HVAC systems, whether in commercial buildings or residential applications, still rely on motors that cycle on and off throughout the day. This start-stop behavior, inherited from older control logic and motor technology, creates more than just noise. It’s a major source of inefficiency, mechanical wear, and acoustic vibration.

Soft magnetic composites (SMCs) are more than a materials swap for motor cores; they enable a critical rethinking of motor architecture for modern HVAC systems. In variable‑speed, inverter‑driven applications where motors run long hours at partial load, the magnetic core defines torque smoothness, losses, noise, and long‑term reliability. This article walks engineering teams through the material science, geometry, torque behavior, hybrid‑core strategies, and thermal and acoustic benefits that make SMCs a system‑level advantage for HVAC design.

Even as HVAC systems adopt smart sensors, variable-speed drives, and connected controls, one component hasn’t kept pace: the traditional laminated-steel motor core.

Standard HVAC motors operate at 85–92% efficiency, which looks respectable but hides a massive opportunity. Across the global HVAC installed base, even a 2–5% efficiency gain can translate into billions of kilowatt-hours saved.

Humanoid robots are redefining how machines move, but the motors driving them are still stuck in two dimensions. To replicate human motion, you need compact actuators that can twist, bend, and pivot naturally across multiple axes. That’s where the spherical pan-tilt motor changes everything.

Imagine walking into a hospital where a robot greets you at the door, wheels a supply cart down a crowded hallway, and assists nurses with lifting heavy trays—all without slowing down workflow or needing special infrastructure. That’s the promise of humanoid robots: machines built not just to work for humans, but to work and engage with us in the spaces we already inhabit. Unlike traditional industrial robots that are locked inside cages, humanoids are designed to fit into our world, navigating stairs, handling objects, and moving with human-like dexterity.

People. Passion. Powdered Metal.

293 Battery Street

St. Marys, PA 15857

(814) 834-4004