Experts have been saying for years that many industries will soon need new and better materials for their electromagnetic applications. That future is now.

Innovation-minded engineers are looking to a new solution for electric motor designs and similar applications. Powder metallurgy may be your best soft magnetic material solution for both AC and DC applications.

The best way to use these materials is powder metal, where you can shape them freely. In powder metallurgy, these materials fall under two umbrellas: soft magnetic composite materials (SMCs) and sintered soft magnetic materials. This resource center will help you understand which is better for your project, as your solution may differ by application, industry, or property needs.

Click below and we’ll take you to the appropriate starting point:

Uses of Sintered Soft Magnetic Materials (DC applications):

Uses of Soft Magnetic Composites (AC applications):

Soft magnetic composites and sintered soft magnetic materials have two distinct ranges of applications.

To understand why, look at the way manufacturers treat these materials. Sintered soft magnetics, as the name implies, undergo a higher-temperature treatment (sintering) for particle-to-particle bonding to improve strength and ductility (among other properties). They also give you the option of alloying materials. SMCs receive a lower-temperature treatment to preserve the individual particle identity. This process change minimizes heat inefficiency and maximizes magnetic performance.

What does that look like in practice? If you specified an SMC for a steering wheel component, the response would be too slow and the driver would end up crashing into a tree. Similarly, if you put sintered soft magnetics in an AC electric motor design, the motor essentially becomes a giant heater that’s wildly inefficient.

We implore you to learn more about each material. When used correctly in the right application, they’re superior to every competing process on the market.

If you’re already experimenting with new electric motor solutions that are a little different, consider incorporating powder metallurgy into your plan:

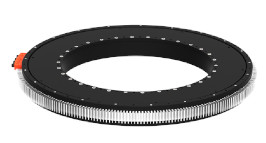

In SMCs, each particle is a discreet magnetic element. We achieve this by adding a magnetic resistive coating to each particle. You can minimize heat buildup/eddy current losses, particularly at higher frequencies above 200 Hz, while adding the flexibility of 3D design. Compared with steel laminations, soft magnetic composites can offer superior efficiency -- both in magnetic performance and material use.

Soft magnetic composites are often the best material for AC custom electric motor design when you need a higher level of performance.

SMCs offer AC electromagnetic design possibilities that didn’t exist previously:

For example, a low-speed rotor is highly compatible with SMCs -- the stresses are lower than you think. In a ceiling fan motor, you can combine SMCs and traditional lamination steel to achieve multiple properties and reduce the assembly size.

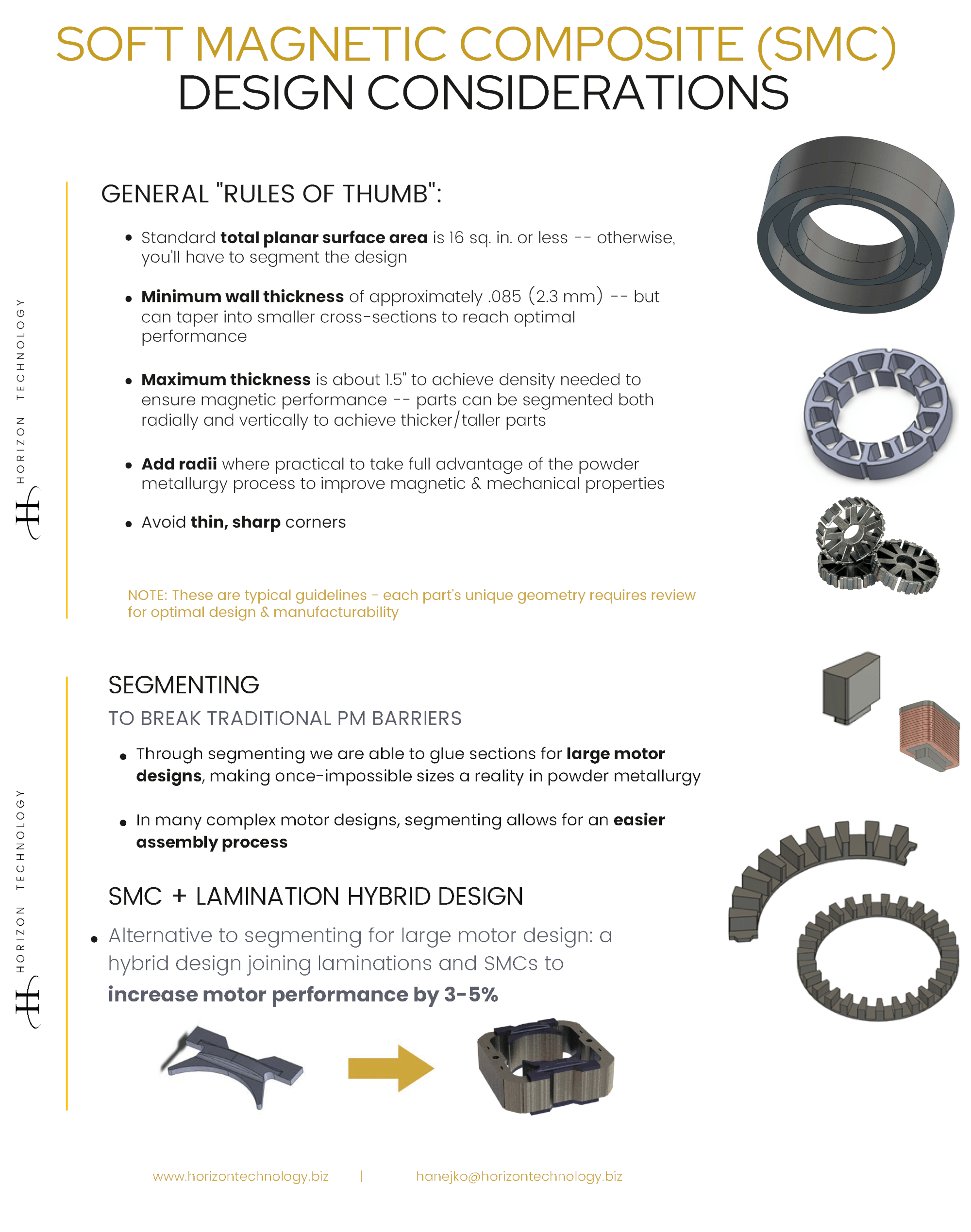

(Open graphic below in new tab to see full-scale version.)

Since alloying is only feasible in sintered parts, that’s the route you’ll take if you need the properties of phosphorus or silicon in your component.

Sintered soft materials are ideal:

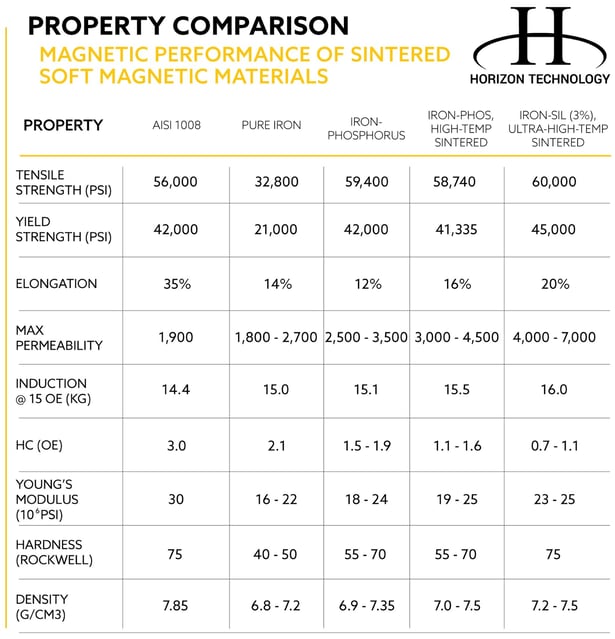

Engineers commonly compare stamping vs. powder metallurgy. We’ll make it easier for you by showing the numbers for stamped steel laminations vs. sintered powder magnetics. You’ll see that in powder metallurgy, the properties of soft magnetic materials give up very little in terms of performance:

Fran Hanejko, our Senior Advanced Materials Engineer, is an industry-leading expert with numerous published research papers under his belt.

Are you completely in the dark on soft magnetic powder? All brushed up on the basics of electric motor materials but need a little more research? Or somewhere in between?

Keep reading to learn what makes powder metal materials so important to electromagnetic components in motors and more:

This paper explores the advantages and disadvantages of single-sided and inside rotor axial flux geometries when considering permanent magnet synchronous machines.

Our world is focused on making electrical devices faster, lighter, and overall better. Why should motors be any different? Soft magnetic material allows for revolutionized designs of electromagnetic devices. That translates to improved efficiency and reduced weight and costs -- without sacrificing magnetic performance.

Have you ever wished you had superpowers that could stop both hysteresis and eddy current loss in a project that demanded high magnetic performance? An inefficient magnetic part can bring down your whole design. A little lesson about materials can show you how to minimize hysteresis and core loss in induction motors and other AC applications.

Powder metallurgy is breaking into more and more electrical applications, but how does it stack up (literally) against those old-school electrical steel laminations? Turns out some electrical steel uses and applications should stay as such, while sometimes powder metal is a great alternative. Let’s look at why engineers are still working with electrical steel and whether you’re missing out on opportunities in some cases.

SMCs are today a viable alternative to steel laminations in a range of new applications, such as rotating machines, fast-switching solenoids, and sensors. And you can do it while creating a fraction of the components per product! This paper focuses on how material properties are affecting the performance of a novel motor design.

Which is easier to worry about -- 1,300 components or 10 components? For decades, manufacturers have accepted as law the obstacles associated with standard lamination steels. But the emergence of soft magnetic materials for use in auto and motor parts should not be ignored by those seeking a truly unique, remarkable part. How do SMCs compete with lamination steels? Let’s take a look.

Powder metal does more than you might think -- if you’ve got the right material. Knowing the strengths and subtleties of each material process can make your product stand out in a competitive market. Three emerging material processes you should know about ASAP are the 1P, 3P, and 5P soft magnetic composites. Here’s how each material will bestow certain qualities on your application.

The chance to move from 2-D to 3-D design of electrical machines is possible thanks to soft Magnetic composites. These iron-based powders are insulated and pressed to realize shapes otherwise impossible with traditional lamination sheets. This paper presents recent progress in mixing SMC iron powders and phenolic resin, in different weight percentages and mold pressures. The goal? Compromising between magnetic and mechanical qualities.

With the electrification of the automobile continuing at an accelerated pace, many wonder what type of motor is best for the modern electric drivetrain. There’s a strong argument to the permanent magnet motor being superior to the three-phase induction motor. The inherent advantages of powder metallurgy -- potential for increased motor performance and lower overall cost -- can be an effective tool in producing these drive systems.

Manufacturers of wind turbines and electric machines always had to find a balance between using generators with low-weight, low-reliability systems and using heavy, high-efficiency systems. A new generation of motors and generators based on axial flux technology combines the best of both worlds. This blog post describes the difference between axial and radial flux technologies.

In many cases, soft magnetic composites aren't a cost-effective or good 1:1 replacement material for steel electrical laminations. But, what if you could marry SMCs with laminations to get an answer where 1 + 1 = 3? Here we unveil something that’s more of an opportunity than a case study of a finished application. But that doesn’t make it any less exciting!

This article begins by introducing the importance of electrical steels in their application as electrical machine cores. At the center of the discussion? The origin, controlling factors, and methods of optimizing core loss -- SMCs’ most important magnetic parameter. Powder composite materials are now making their way into niche power device applications, so the article compares their magnetic properties with lamination steels’.

Most HVAC systems, whether in commercial buildings or residential applications, still rely on motors that cycle on and off throughout the day. This start-stop behavior, inherited from older control logic and motor technology, creates more than just noise. It’s a major source of inefficiency, mechanical wear, and acoustic vibration.

Soft magnetic composites (SMCs) are more than a materials swap for motor cores; they enable a critical rethinking of motor architecture for modern HVAC systems. In variable‑speed, inverter‑driven applications where motors run long hours at partial load, the magnetic core defines torque smoothness, losses, noise, and long‑term reliability. This article walks engineering teams through the material science, geometry, torque behavior, hybrid‑core strategies, and thermal and acoustic benefits that make SMCs a system‑level advantage for HVAC design.

Even as HVAC systems adopt smart sensors, variable-speed drives, and connected controls, one component hasn’t kept pace: the traditional laminated-steel motor core.

Standard HVAC motors operate at 85–92% efficiency, which looks respectable but hides a massive opportunity. Across the global HVAC installed base, even a 2–5% efficiency gain can translate into billions of kilowatt-hours saved.

Humanoid robots are redefining how machines move, but the motors driving them are still stuck in two dimensions. To replicate human motion, you need compact actuators that can twist, bend, and pivot naturally across multiple axes. That’s where the spherical pan-tilt motor changes everything.

Imagine walking into a hospital where a robot greets you at the door, wheels a supply cart down a crowded hallway, and assists nurses with lifting heavy trays—all without slowing down workflow or needing special infrastructure. That’s the promise of humanoid robots: machines built not just to work for humans, but to work and engage with us in the spaces we already inhabit. Unlike traditional industrial robots that are locked inside cages, humanoids are designed to fit into our world, navigating stairs, handling objects, and moving with human-like dexterity.

People. Passion. Powdered Metal.

293 Battery Street

St. Marys, PA 15857

(814) 834-4004