In the intricate array of modern manufacturing, the Powder Metallurgy (PM) industry stands as a dynamic force, continually shaping the future as a sustainable metal forming technology. As we navigate through the current landscape of PM, it becomes evident that innovation is not merely a choice but a necessity.

The Current Pulse of Powder Metallurgy

Efficiency, Sustainability, and Precision: The Pillars of PM

At its core, Powder Metallurgy is driven by the pursuit of efficiency, sustainability, and precision. The process involves compacting powder metal in a closed die, followed by sintering and, if necessary, additional thermal treatments to achieve desired mechanical properties. With a rich history of being recognized for its cost-effectiveness, the PM industry is currently navigating another market shift, compelling manufacturers to push the boundaries of innovation to unprecedented heights.

Automotive Evolution: A Paradigm Shift

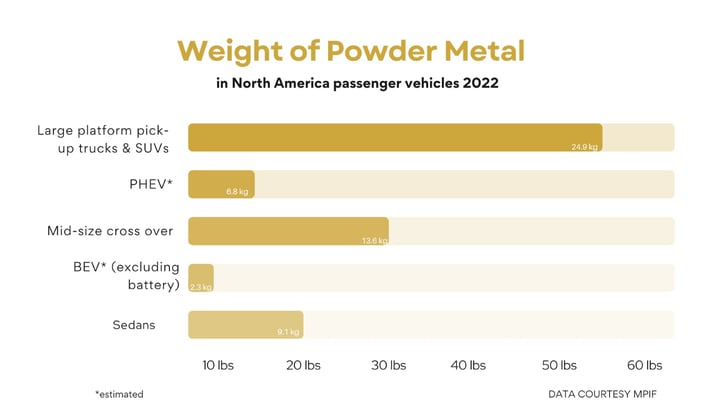

The automotive industry is undergoing a seismic shift towards electrification, PM faces a pivotal moment. Demand for electric vehicles, hybrids, and downsized internal combustion engines is surging globally. The traditional stronghold of engine and transmission components is being redefined, presenting challenges and opportunities necessitating a paradigm shift in PM material design and manufacturing processes.

Rising Trends: Navigating PM’s Future

1. PMs History with Structural Components - Redefined

Structural components have been the driving force behind the Powder Metallurgy (PM) industry. PMs unique capacity to fabricate intricate and precisely designed structural elements – is now being pushed to produce even higher strength components. The synergy between new materials and advanced processing methods promise a dynamic future where precision, efficiency, versatility and high strength converge to redefine the possibilities.

2. Electrification Demands Advanced PM Solutions

As electric vehicles become more common, the demand for specialized soft magnetic PM components rises. This includes sintered soft magnetic components crucial for the growing number of electric motors and solenoids in modern vehicles. The ability to adapt to diverse material alternatives and processing methods is key, a trend Horizon Technology has keenly embraced.

3. Soft Magnetic Composites: A Transformative Frontier

Soft Magnetic Composites (SMC) have emerged as a transformative technology within PM. Horizon Technology's exploration of SMC components showcases the potential for 3D design freedom, reduced core losses, and high material utilization. The company is not merely keeping pace with this trend but is actively shaping its trajectory.

4. Sustainable Innovations: Greening the PM Landscape

Sustainability is not just a buzzword; it's a commitment woven into the fabric of modern manufacturing. Powder Metallurgy is positioned as a preeminent green technology - exceeding 95% material efficiency and over 15% energy savings compared to other metal forming technologies.

The Horizon Unfolding: A Trailblazing Journey

As the PM industry charts a course into uncharted territories, Horizon Technology leads the way, steering with innovation, sustainability, and client satisfaction as its compass. The journey is not just about meeting today's demands but anticipating and shaping tomorrow's needs. For a closer look at the unfolding horizon, visit www.horizontechnology.biz and witness the future of Powder Metallurgy.