When most people think about the powder metal industry, they only think of structural components that are ever-evolving to meet the needs of the marketplace. However, emerging trends in both industrial and transportation sectors require a re-engineering of AC and DC electrical performance.

How is powder metal adapting to meet this demand?

Today's powder metal material properties, in particular, are highly diverse. The processing method is also very scientific, and admittedly can cause headaches if you’re a purchaser or wet-behind-the-ears engineer. Sometimes it’s easier to visual things in chart form.

This flow chart categorizes powder metal (PM) materials into three groups based on performance needs. If you want a full description of a certain branch, click your link of choice below to skip forward to it.

- Soft magnetic composites -- rare levels of magnetic performance

-

Sintered soft magnetic materials -- optimized balance of strength and magnetic performance

- Structural iron-carbon materials -- for high-strength, non-magnetic applications

In general, as performance increases in each category, so does price.

There are all sorts of material grades, and all sorts of ways an advanced powder metallurgy manufacturer can customize them to fit your needs. What are the most important 1-2 qualities in your part? What are your non-negotiables?

Here's a look at each material/need in greater detail:

Soft Magnetic Composite Material Properties

Soft magnetic composites (SMCs) are compacted, but instead of being sintered, they get a lower-temperature heat treatment to cure the insulation product around each particle.

SMCs are great electric motor core materials for AC applications, from bathroom fans to e-bikes.

We're not providing the standard sliding scale for these materials. Why? The massive range of customizability and performance data ranges.

We go into SMC component projects with a higher cost expectation. Then, as we test, we narrow down your needs to get the best component possible at a reasonable price point.

Because SMCs are so customizable, they require interactive discussion to find the right solution. Have a project you'd like to consider SMC for, but not sure where to start? Fill out this form, and we'll send a customized answer. If you're not ready, simply skip it and keep learning below!

SMC Performance Trait Audit

A quick explainer of shape complexity: This trait can influence material and process choice, though all powder metals benefit from the inherent shape-making capability of PM. Here are examples of what's considered low, medium, and high complexity in PM shapes (in that order):

As for the other measurables you should be asking yourself about, they include.:

- Core losses

- Permeability

- Frequency response

- Strength

Note that the strength of magnetic powder metal parts can be higher than their reputation! Each main category of SMC has slight variations in strength.

Here we've created five hypothetical AC material solutions, rather than show you specific grades. Each addresses a common need in AC electric motor design and similar projects:

- Horizon example #1: High-permeability material. A key trait in many magnetic parts.

- Horizon example #2: High-strength material. Note that the "8,000+" psi option in the form above is more of a working goal than something immediately available. May be steam treated to improve tensile strength. May include a magnetic oxide coating to add permeability and strength.. Moderate core losses.

- Horizon example #3: Low-to-moderate cost. Moderate permeability, losses, and frequency response (up to about 2,000 Hz). Low strength. May have relatively low resistivity.

- Horizon example #4: High-frequency material -- up to 10,000 Hz and above. May be able to achieve high density. Moderate strength, low permeability, and low losses. Higher cost.

- Horizon example #5: Low-permeability, unique materials for specialty applications. Do you have an idea out of the ordinary? You’d be surprised what kinds of creative solutions PM can bring to reality.

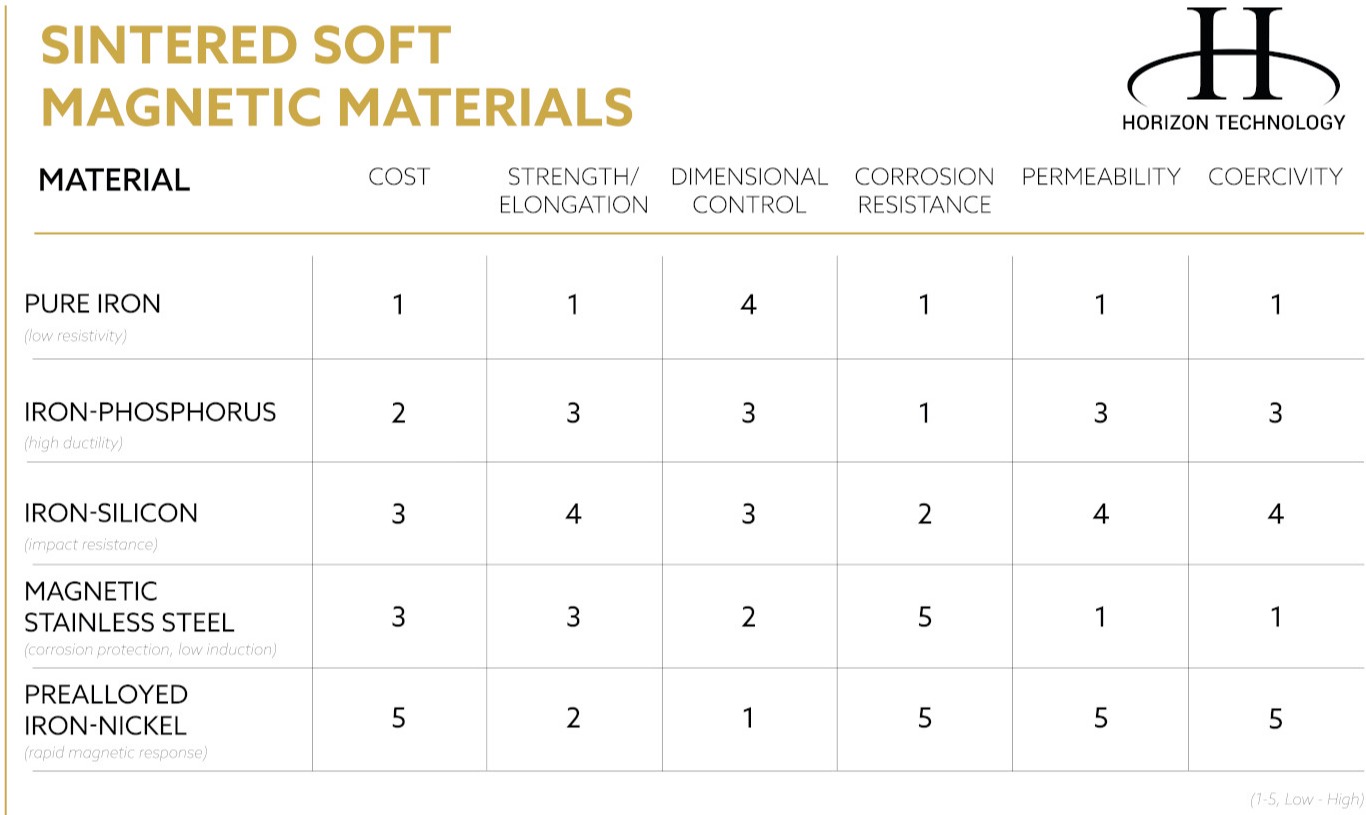

Sintered Soft Magnetic Material Properties

Soft magnetic powders enhance or channel the flux a DC electric current produces. The sintering step makes sure the powder behaves as expected after your part is formed.

In general, sintered magnetics are a happy medium between structural materials and soft magnetic composites. What's more, they're evolving as we speak to even further improve DC electric motor performance.

Here they are, in order from lowest cost and performance to most expensive and highest performance:

1. Pure Iron

Pure iron powder grades are born from atomization or reduction. These powders are the basis for most mixes of low-alloyed sintered steels.

High-purity iron has excellent soft magnetic qualities. A vendor can use coated or insulated iron to add new design options to your tool kit.

Note that resistivity in pure iron is very low.

2. Iron-Phosphorus

Iron-phosphorus materials feature high induction, strength, and hardness. Their resistivity is better than iron, but still not good.

It’s notable that this alloy’s high ductility allows for riveting operations.

3. Iron-Silicon

Iron-silicon sintered parts respond better than iron-phosphorus sintered parts to moderate frequencies. It can take a hit, so this material sees use in application where impact is involved.

These powders are also useful in applications where high surface areas are on your wish list.

4. Magnetic Stainless Steel

Stainless steels used in powder metallurgy are mainly ferritic grades most common in corrosive environments. Martensitic stainless grades 409L and 434L are good examples.

Note that this category says “magnetic,” unlike the previous entry on stainless steel. The popular 300 series of stainless steel grades is NOT magnetic.

As for induction, stainless steel generally has a lower rate than iron or iron-phosphorus powders.

Some powder metallurgy companies can combine a non-magnetic stainless steel part with a magnetic part to assemble a unique application.

5. Prealloyed Iron-Nickel

Iron-nickel prealloyed materials are 50% nickel and 50% iron.

Nickel is unique among nonferrous metals in that it’s magnetic. It’s great for applications requiring high corrosion resistance.

Low induction and low applied fields are trademarks of iron-nickel. Thanks to its high permeability, this material provides lightning-fast response to an applied current. High density is achievable, too.

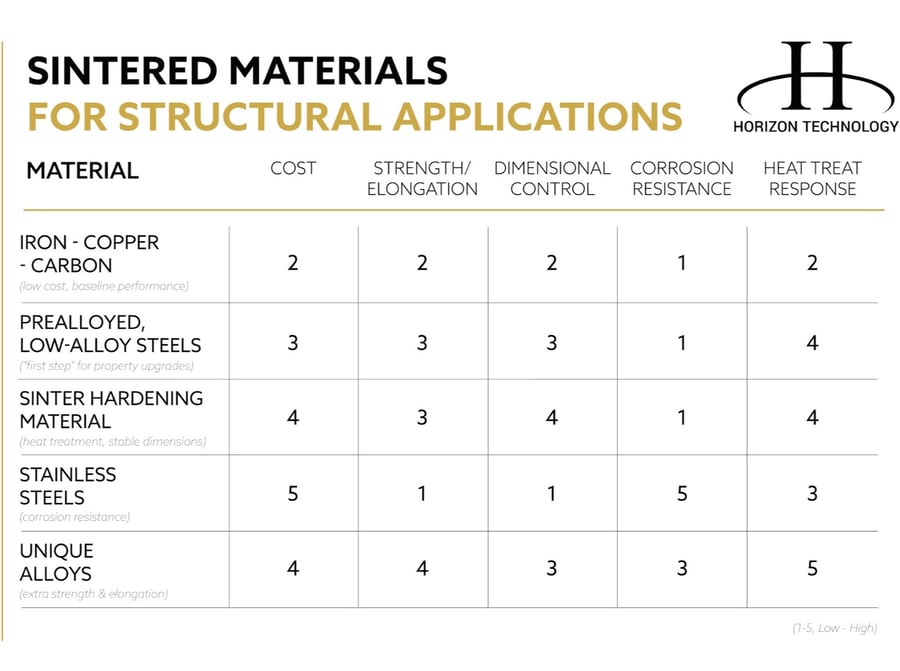

Structural Powder Metal Material Properties

This family of PM materials are premixes of iron and graphite to form essentially carbon steels. They're used in applications such as self-lubricating bearing and many shock absorber components.

In order from lowest cost and performance to most expensive and highest performance, they are:

1. Iron-Copper-Carbon

Purchasers have long considered it the standard for powder metal materials -- at least 50% of North American powder metal parts are made from iron-copper-carbon (ICC).

While there’s a decent amount of dimensional change during the manufacturing process with ICC, it’s a well understood material. Most manufacturers can keep a handle on it, and have accepted it as the norm.

Think of ICC as merely a starting point for powder. It's a low-cost material that provides adequate performance for many applications. For more advanced or unique applications, consider exploring the dozens of other possibilities out there.

2. Prealloyed, Low-Alloy Materials

These PM materials have all of their alloying elements combined with the iron during the melting stage of iron powder production. Typically, the most common alloying elements used in iron powder metallurgy are molybdenum, nickel, and to a lesser extent chromium. The advantages of these materials are a uniform microstructure after heat treatment.

This material group represents the first step in improving properties in your structural application.

3. Sinter Hardening Grades -- for Heat Treatment & Dimension Stability

Sinter hardening is a process in which the PM part can be cooled quickly after the sintering process to generate a predominantly martensitic microstructure. These materials generally have greater alloying content than traditional pre-alloyed, low-alloyed materials.

The advantage of these materials is their ability to reduce dimensional distortion and component cost. This is thanks to superior heat treatment response -- the manufacturer can skip a separate quenching step when using sinter hardening grades.

4. Stainless Steel

Stainless steels have inherently much greater corrosion resistance compared to steel materials. Typical grades include the 300 and 400 series, plus some precipitation hardening grades such as 17-4 PH. For extreme protection against corrosion in marine environments (or where roads are frequently salted), there's 316 stainless steel.

One risk in these materials is that sintering them at high-temperatures causes a lot of dimensional variability.

5. Unique Alloys -- for Extra Strength & Elongation (or Something Else!)

Because PM materials use a premixing step prior to compaction; it's possible to incorporate specialized additives that can give unique physical properties. For example, it's possible to incorporate additives that expand:

- Dry lubrication

- Wear resistance

- Corrosion resistance

- Use of nontraditional alloying elements

If the additive can withstand the sintering step, you can significantly expand the potential applications for powder metal -- and its strength, elongation, and shape-making advantages.

If you’ve got something a little out of the ordinary, find a powder metal manufacturer willing to try it!

A Solution for Practically Every Application

Powder metal materials don’t really fit in a box. Advanced manufacturers can take standard materials far beyond what you’re used to:

-

Higher magnetic performance

-

Higher part density

-

Unique sintering conditions for added strength

To learn more about other competitive design advantages and drawbacks of powder metallurgy vs. stamped laminations, machining, forging, and casting, grab this free e-book:

(Editor's note: This article was originally published in January 2019 and was recently updated.)