A discussion about the efficiency and performance possibilities of modern metal manufacturing is incomplete without the concept of sintering in powder metallurgy.

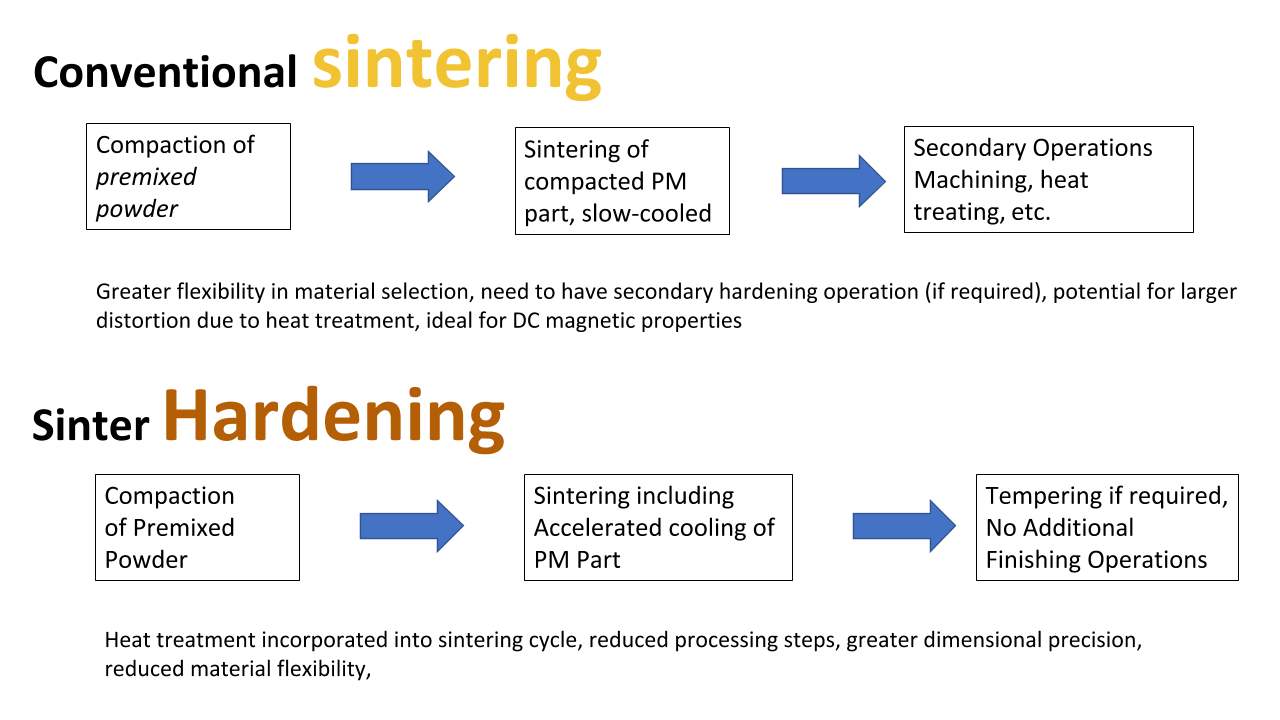

What is sintering in powder metallurgy (PM)? Conventional sintering processes are the bread and butter of improving a part with PM. This process heats the compacted part to fuse the loosely bonded particles for improved strength and hardness. After sintering, the powder metal part is often heat treated by reheating to permit quenching and tempering. This further increases the hardness and strength of the compacted component.

One advantage of powder metallurgy is the ability to sinter the part and then, thanks to controlled cooling, create a wide variety of strength and hardness combinations. At one end of this range is very slow cooling to create a soft magnetic part; the other extreme is effectively atmosphere quenching the part to form a martensitic structure with the same hardness as quenching -- but without the additional processing.

Out of several metal hardening process types, sinter hardening stands out. Why? It combines the benefits of sintering and hardening into one operation. You minimize secondary operations and enjoy greater dimensional precision.

For the metallurgically savvy: Conventional heat treatment (reheating and quenching) forms martensite within the part that has high hardness but is quite brittle. Tempering lowers the hardness slightly but dramatically increases the strength. This has been the tried-and-true method for hardening in both PM and conventional parts manufacturing.

However, using special sintering furnaces coupled with engineered powder materials creates the opportunity to eliminate the reheating step and merge it into the sintering step. You get the same transformation along with the benefits of strength and hardness.

Let’s go deeper into what makes sintered metal parts and hardening stand out from other heat treatment services and competing manufacturing processes.

Defining Sinter Hardening & Conventional Sintering Processes

During this particular form of heat treatment, heat is applied under a controlled atmosphere so the temperature peaks below the melting point of the primary metal in the mix. Today, special sintering furnaces eliminate the need for expensive post-sinter heat treating. The end result is a part that’s either finished or semi-finished, requiring no or very little secondary machining.

Sinter hardening is an accelerated cooling process under the heat treatment umbrella. Where it differs is that it increases the hardness of the metal, making it more resistant to deformation when placed under stress.

Sinter hardening eliminates the need for a secondary quench hardening treatment and provides better dimensional control. An accelerated process, of course, can keep down production and labor costs.

The obvious reaction is that this is a potential cost savings. But we’ll also discuss the environmentally friendly nature of this operation. You're saving the planet in addition to getting more bang for fewer bucks in terms of tolerances and stackups!

Sinter Hardening Vs. Other Heat Treatment Processes

There are several heat treating processes available in metal manufacturing. But today your manufacturer can sinter harden a part, effectively heat treating and sintering it at the same time.

Imagine all the energy that goes into sintering a part. Then you have to re-establish all that energy to (conventionally) heat treat the part. In the era of energy efficiency, sinter hardening can save 60% of the energy cost required to heat treat a PM part. This is a great way to advance of the idea of powder metal parts being “green.”

Energy use affects your production cost, so the comparison below may interest you: Think of the numbers as a ratio of time and effort it takes to complete each process:

|

Conventional sintering, |

Sinter hardening, |

|

Conventional sintering: 1.0 |

Conventional sintering: 1.0 |

|

Heat treatment: 0.6 (could be higher depending on the operation) |

Heat reheating: 0 |

|

Tempering 0.1 |

Tempering 0.1 |

|

Total: 1.7 |

Total: 1.1 |

Proper heat treating controls the hardness and strength of the final part. Your friendly powder metallurgy company can achieve some performance properties through careful sintering alone. But compared with traditional heat treatment, sinter hardening can give components comparable qualities and better dimensional precision.

Other heat treatment processes include:

- Quenching and tempering

- Carburizing

- Precipitation hardening

- Tempering (also used when you sinter harden a part)

Tempering may increase toughness, but it can also result in a loss of hardness.

(Related article: Toughness Vs. Hardness)

Sintering Cost Vs. Other Heat Treating Processes

Powder metal is literally a crucial component of low-cost manufacturing for the automotive industry (and potentially others). The many advantages of powder metal eliminate the need for higher-cost forming technologies associated with other means of fabrication.

Sintered metal products have great net-shaping capability and eliminate or reduce the need to include costly metal removal processes into the production line. This also leads to a great reduction in waste and scrap byproduct, which improves profitability and meets the standards of eco-conscious companies (and states and nations!).

OK, But What About Performance?

With higher strength and hardness, sinter hardened parts offer excellent performance for a variety of industries. Their durability and adaptability have made them proven successes in:

- Gearing

- Lawn and garden equipment

- Firearms

- Aerospace applications

- Military applications

- Automotive production

Engineers in these industries who seek out one of the few powder metallurgy suppliers with sinter hardening capabilities will hold a competitive edge.

Beyond the Typical

Remember: No additional thermal processing necessary!

If you think combining sintering and hardening into one easy step makes sense for you, discuss your end use and performance needs with your powder metal manufacturer. Chances are, powder metallurgy is a cost-efficient alternative to your current way of doing things.

Not every PM manufacturer has these capabilities. Even rarer is the manufacturer that can simultaneously sinter harden while sintering at high temperatures and ultra-high temperatures. Inquire with your manufacturer before coming up with a plan that involves these advanced types of sintering in powder metallurgy.

To get more information on the sintering process in powder metallurgy -- and how it affects your part's performance, ask an engineer below or view our additional resources:

Related Resources:

- What Is Sinter Brazing?

- Powder Metal Materials: A Flow Chart of Possibilities

- What Is Sintered Soft Magnetic Material?

(Editor's note: This article was originally published in July 2019 and was recently updated.)