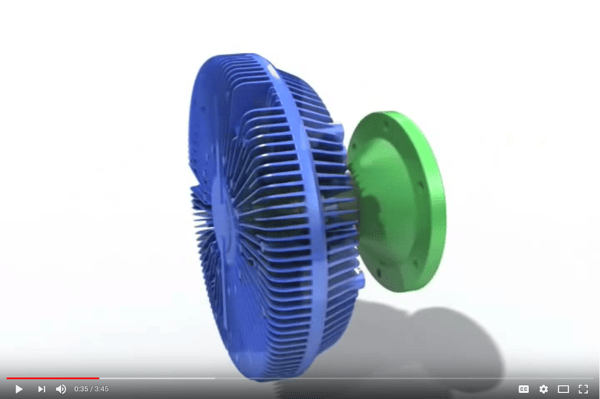

Viscous fan drives may not be well known, but they provide a great service to engines -- while helping drivers save on fuel and maintenance costs. Horizon's flux ring is at the heart of the viscous fan drive (also referred to as a fan clutch).

See how this very technical powdered metal part produces a big impact for heavy-duty truck manufacturers.

To watch a video of the fan drive, click here or the image below.

What Is a Viscous Fan Drive?

Fan drives are an essential part of a heavy-duty truck's cooling system. The fan drive helps pull air in through the radiator to cool the engine. Truck engines can become very hot, especially when trucks are idling, like in a traffic jam. It's essential to cool down the engine before it overheats, or the engine could sustain significant and incredibly expensive damage.

What Is a Flux Ring?

The goal of this part is to provide the electrical connection between the valve and the ECU.

The clutch is actuated based on the fan speed signal, which is sent to the ECU -- this includes the spinning flux ring Horizon produces.

The video above shows the magnetic and flux current and how it operates the valve.

Advantages Over a Fixed Fan Drive

Viscous fan drives not only perform the essential cooling service of a fan drive, but also operate at variable speeds. This gives them a competitive advantage over fixed fan drives. Viscous fan drives engage and disengage less frequently than their fixed-speed counterparts, which:

- Reduces clutch wear

- Reduces dust buildup

- Gives the clutch a longer life span

What's more, viscous fan drives actually delivers power to the engine, saving fuel mileage and reducing wear and tear on the engine. With more efficient use of fuel and less wear and tear come reduced maintenance, so the financial savings add up quickly.

How Does a Viscous Fan Drive Work?

In a viscous drive, the main shaft turns at RPM proportional to the engine speed, while the drive housing attached to the engine fan maintains a separate speed, set by the electronic engine control module. In other words: The fan clutch speed is independent from the engine’s RPM.The fan drive's valve, clutch, and fluid reservoir all spin together, which puts less drag on the engine.

Even better, the cooling fan in a viscous drive can vary its speed to meet precise engine cooling requirements and cooling system temperature. A fixed fan can only run at one speed.

A viscous fan’s more efficient design cuts down on drag across the power spectrum. The fan speed signal and clutch allow for precise engine coolant and charged air adjustments, improving efficiency.

The valve arm opens to push silicone oil in to the working chamber. As the silicone oil flows between the input and output clutch plates, it creates shear forces. This gradual buildup forces the two plates to spin at similar speeds, thus allowing a smooth change in the fan speed.

Since the fan slows when when high power is not needed, your vehicle gains horsepower and torque for better engine performance and mileage. When cooling is needed, the engine control unit (ECU) triggers the clutch, which puts the fan into faster rotation again.

Integral to all of this? The flux ring, which fits inside the fan drive and supports fan drive performance.

The Difference in a Horizon Flux Ring

The Difference in a Horizon Flux Ring

You might have noted the extraordinary aspect ratio between the length and the width of the component. The height makes this flux ring complex and difficult for other powder metal manufacturers to produce.

With powdered metal parts, if you need a part width of 0.100, you normally wouldn’t specify a length of more than 0.800. But this flux piece is 16:1, which is double a normal ratio for a part this thick.

All this is done while maintaining the magnetic performance of the part.

Re-energize Your Design

As you can see in the video, the flux ring and fan drive as a whole plays a big role in improving vehicle performance.

Looking for other ways to re-energize an automotive or other electric motor-based application? Get in touch with us here or request a quote below.