Sintering Process for Powder Metallurgy | Advantages & Disadvantages

- Horizon Technology

- 02.25.2021

- Powdered Metallurgy

At this point, we all know that powder metallurgy can make small, complex parts for a variety of industries, including: Electric motors HVAC Automotive Firearms Lawn and ...

READ MORE

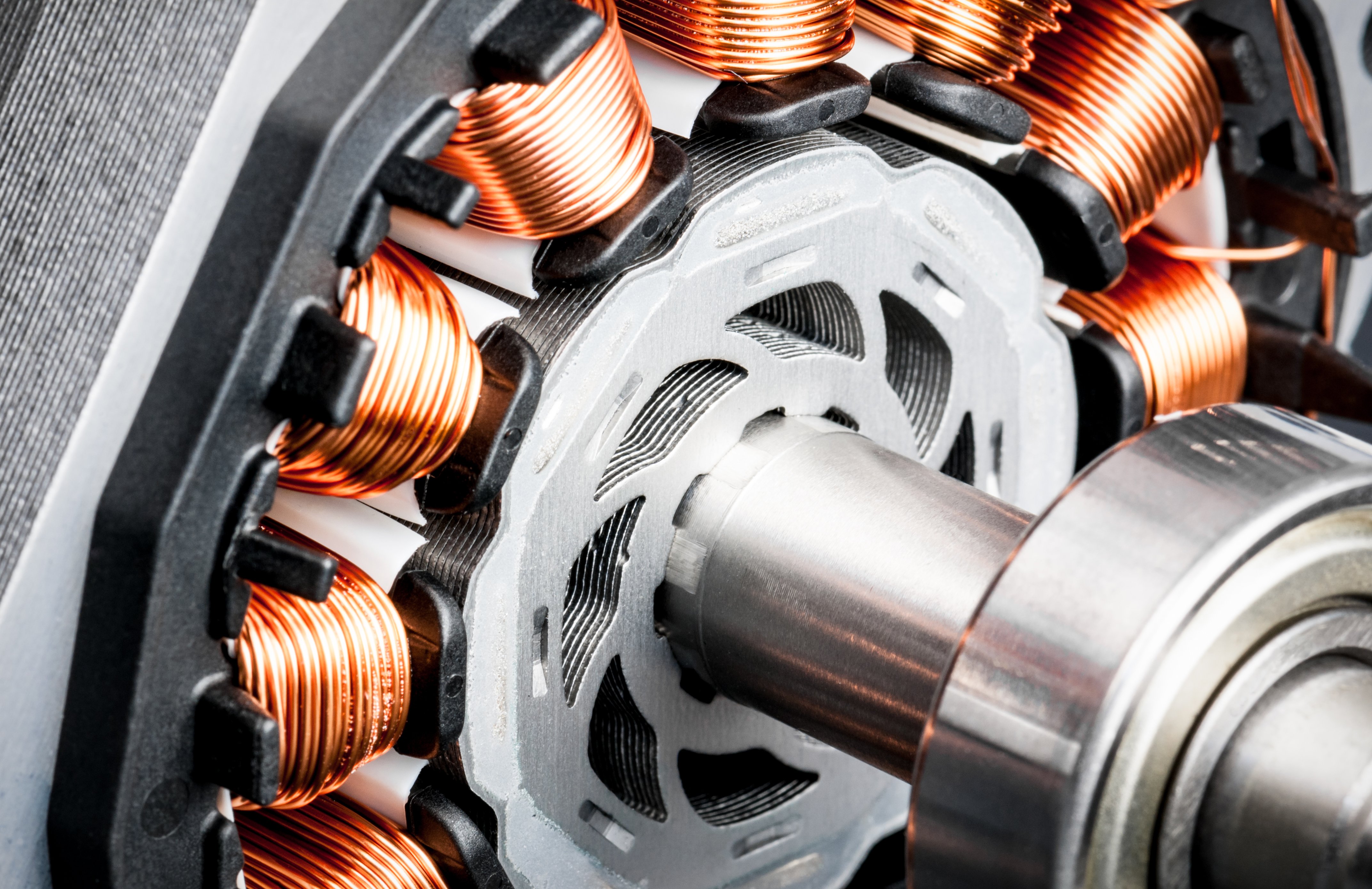

BLDC Motor Design: Segmentation Using Powder Metallurgy

- Horizon Technology

- 02.04.2021

- Powdered Metallurgy

We have well established the benefits of using SMC materials in stator applications compared to lamination steels. SMC powder metal can improve performance and reduce ...

READ MORE

Replacing Forging Applications with Advanced Powder Metal Technology

- Horizon Technology

- 12.28.2020

- Powdered Metallurgy

If you’re considering forged parts for your manufacturing and assembly needs, you probably know that closed die forging, also known as impression die forging, is a ...

READ MORE

Sinter Bonding & Brazing for Enhanced Shape Making

- Horizon Technology

- 11.19.2020

- Powdered Metallurgy

Powder metallurgy (PM) is a highly unique and nuanced process, even down to the joining of parts. While welding is the obvious choice for many manufacturing processes, ...

READ MORE

Explaining Core Losses In AC Electric Motors

- Horizon Technology

- 09.24.2020

- Powdered Metallurgy

Keeping core losses low in AC electric motors can certainly be a challenge, but when it’s done, it can wildly increase the efficiency of your motor.

READ MORE

The Advantages of Sintering With a S.M.A.R.T. Furnace

- Horizon Technology

- 09.03.2020

- Certifications

Famous automakers around the world rely on the sintering process in powder metallurgy to improve their components’ performance and economic efficiency. New advances in ...

READ MORE

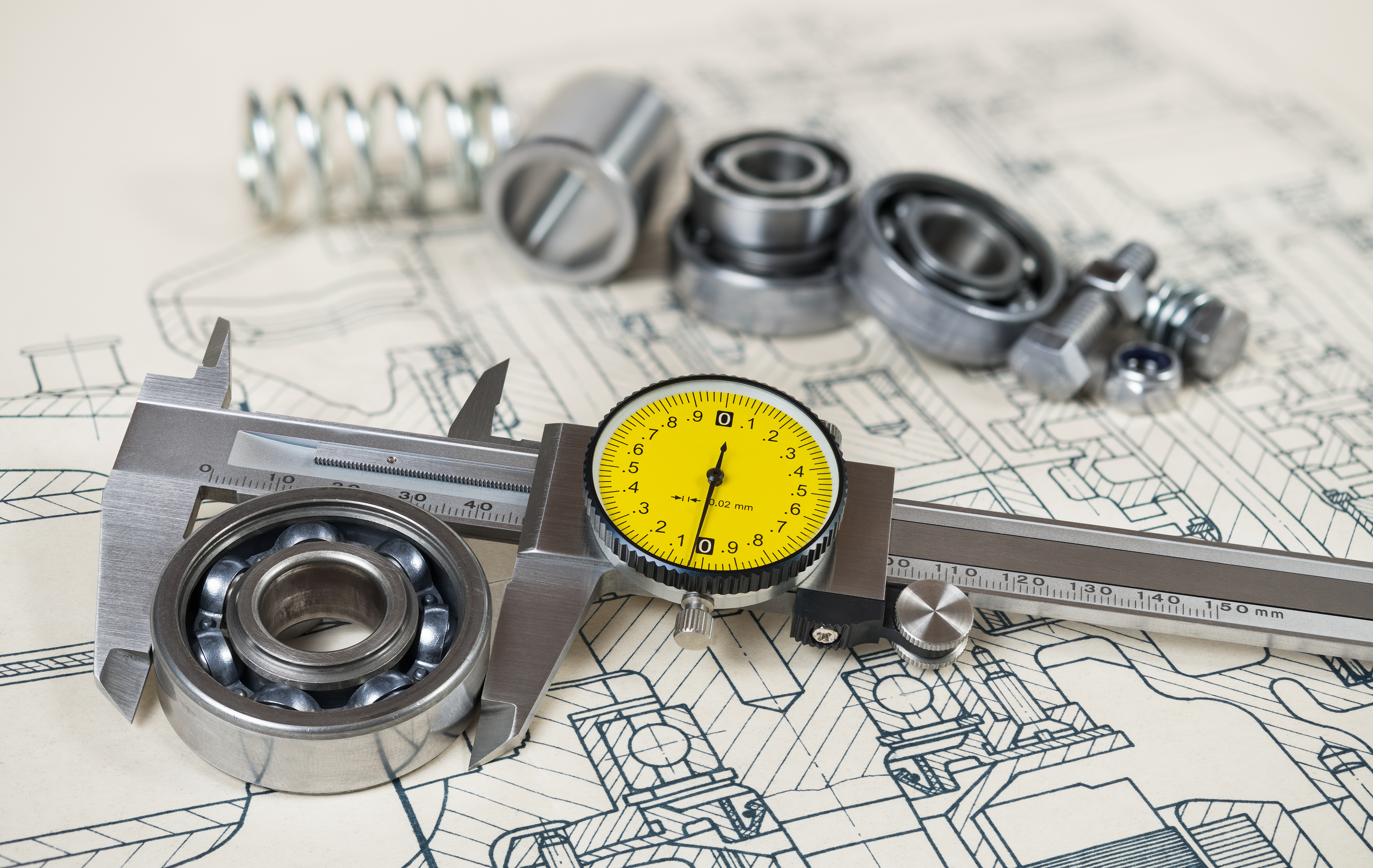

8 Common Secondary Operations in Powder Metallurgy

- Horizon Technology

- 08.14.2020

- Powdered Metallurgy

Making components through powder metallurgy is an exercise in trimming the fat. Its ability to create a net shape part means you can skip some -- or all -- secondary ...

READ MORE

Sizing in Powder Metallurgy: Ensure a Net Shape Part

- Horizon Technology

- 08.13.2020

- Powdered Metallurgy

Sintering is a wonderful way to improve part properties via powder metallurgy (PM). But like any other manufacturing process, it’s not perfect. A component that goes ...

READ MORE

Powder Metallurgy Vs. Stamping: Advantages & Disadvantages

- Horizon Technology

- 07.08.2020

- Powdered Metallurgy

Stamping has produced pieces from cold sheet metal for hundreds of years. In contrast, the powder metallurgy process is even older and involves temperatures that reach ...

READ MORE

Skipping Steps: Sinter Hardening vs. Conventional Sintering Processes

- Horizon Technology

- 06.18.2020

- Applications

A discussion about the efficiency and performance possibilities of modern metal manufacturing is incomplete without the concept of sintering in powder metallurgy.

READ MORE

Recent Posts

Get Updates via Email

ISO 9001:2015

We’re proudly ISO 9001:2015 certified, which means quality assurance at every stage of your project.

Our internal systems have been inspected for reliability and cost effectiveness, and received the seal of approval.

View our ISO 9001:2015 certification.

Plex Systems

Horizon uses Plex Manufacturing Cloud software to meet your strict and exhaustive traceability and quality goals.

Plex's real-time updates let us continuously improve efficiency and customer responsiveness. Your lead times will decrease, and you’ll receive quicker service.