Stamping has produced pieces from cold sheet metal for hundreds of years. In contrast, the powder metallurgy process is even older and involves temperatures that reach well into the four-digit range.

The advantages of powder metallurgy vs. stamping are largely in powder metallurgy’s (PM’s) ability to form a complex, net-shape part. But even we admit PM is not a good alternative to stamping 100% of the time.

These are the pros and cons of the stamping and powder metallurgy processes when you stack them up against each other:

The Basics of Powder Metallurgy Vs. Stamping

Powder metal raw material is often blended from various elements to achieve the combination of strength, hardness, corrosion resistance, and even magnetic properties you need. Powder metallurgy entails compacting metal powder in a die into mostly the finished shape. The "green" parts then pass through a sintering furnace where high temperatures create metallurgical bonds between the powder particles.

In stamping, the manufacturer places a metal sheet, typically less than 0.25" thick, on a die. A punch descends onto the sheet, shearing it around the perimeter and producing a flat, 2D blank.

Even just these basic descriptions of each manufacturing process may have clued you in as to how they each perform. Now let’s look deeper.

Disadvantages and Advantages of Powder Metallurgy Vs. Stamping

These processes have two things in common: Both need tooling shaped to the geometry of the final part, and both can put out high volumes. So what of the differences? They lie in:

- Dimensional precision

- Quality

- Design flexibility

- Affordability (both per part and tooling)

- Strength

- Speed

- Scrap efficiency

1. Precision

Both processes produce profiles with very little part-to-part variability. However, sintering introduces a degree of dimensional distortion that gives the stamping process a small advantage. It should also be noted that PM can produce more than a 2D profile; its inherent advantage is the ability to make 3D shapes with a single stroke of the compaction press.

Note that with powder metal components, it’s important to keep surfaces that’ll be formed by the die and lower pressing as straight as possible. In the stamping process, the sheer must be considered. Many customers don’t realize that In the PM process, you gain the possibility of straight, clean angles.

2. Quality

Both processes yield highly consistent parts. Stamping can leave marks in the metal surface, especially if slugs carry over on the punch.

Powder metal parts inherently have porosity. Depending on your application, this can be a good or bad thing. Fortunately, advanced compaction techniques can get you to a denser, less porous part than in years past.

Where things really get interesting is magnetic performance.

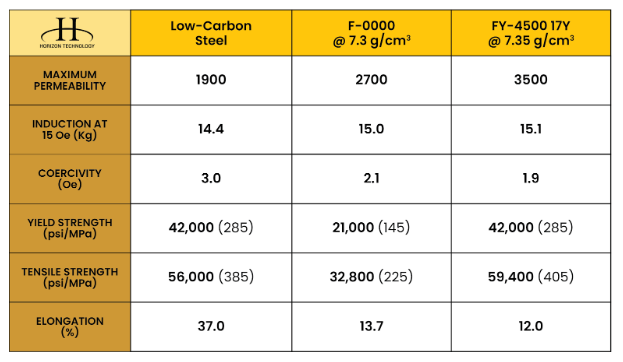

*F-0000 is basically a pure iron with less than 0.03% sintered carbon

*FY-4500 17Y is a pure iron alloyed with 0.45% phosphorus

AISI 1008 is a commonly used steel for stamping. The powder metal materials in the chart above -- F-0000 and FY-4500 17Y -- show …

- Higher permeability (faster response)

- Lower coercivity (overall better magnetic performance)

- Higher induction

… at a given applied field. The strength and elongation numbers are solid, too.

3. Design Flexibility

One of the trademark advantages of powder metallurgy is design flexibility. Think of it in three ways:

- Stamping is restricted to how the metal blank can be deformed and is limited by radii, angles, and dimensions. Powder metal parts can be “sculpted” with material exactly where it's needed, as long as your manufacturer can successfully release them from the die. Think again of the 3D design flexibility.

- A disadvantage of stamping is its poor edge quality. Shearing results in a combination of deformation and cracking, leaving an uneven and unattractive edge. You’re guaranteed to need a secondary finishing operation -- a hassle powder metallurgy avoids.

- Also among the disadvantages of the stamping process is the need for a somewhat ductile/low-strength metal. This limits stamping predominantly to low-carbon steels and nonferrous materials like copper and aluminum. In PM, you can blend metal powders to the exact composition needed by the finished part.

One limitation of powder metallurgy is part size. With taller pieces, the powder metal manufacturer may struggle to achieve uniform density all the way through, or may not even be able to fit it in the compaction equipment.

4. Affordability (Both Per-Part and Tooling)

Per-part affordability is one of the greatest advantages of stamping processes. But PM is not as far behind as you think.

A caveat: The cost-efficiency of both processes largely depends on project volume. It’s rarely going to be cost-efficient to make 10 powder metal stators for your next electric engine design. You could say the same thing about stamping.

If it’s feasible to make your component with the stamping process, then stamping is a very logical, economical choice. However, as a stamped component gets more complex, the price will rise.

If your component is complicated and requires multiple dies or a progressive die, tooling and production costs may dictate that powder metal is more efficient. If multiple stampings are a must, the additional fixture and welding costs make PM even more advantageous. Most powder metal components only require one press operation and one set of tools.

5. Strength

The nature of stamping operations typically limits you to relatively low-strength materials such as low-carbon iron or steel. High-strength materials tend to break the tools.

Stamped parts can be stiffened by forming ribs and other radii, but the material must have some ductility. Meanwhile, advanced compaction techniques and unique material alloys can make some sturdy powder metal parts. Unlike stamping, PM employs copper and stainless steel alloys -- not only are these strong, they also resist corrosion exceptionally well..

6. Speed of Process

Neither powder metallurgy nor metal stamping is ideal for low-volume work.

Powder metallurgy has always been a high-volume technique. If you order a limited number of components, the per-part lead time may disappoint you. It may take the powder metallurgy company almost a month just to get the necessary powder in-house, and you can tack on a few weeks of production after that.

But when you have a need for speed in addition to the many of the qualities above, stick with powder metallurgy. While it’s ill-suited for a 10-part order, it’s incredibly efficient for 10,000-part orders.

To make up for some of the many shortcomings of stamping vs. powder metal, there’s a special type of stamping called fine blanking (AKA fine-edge blanking). This method improves accuracy, flatness, and edge characteristics. But here’s the catch: It suffers from significantly slower production speeds than powder metallurgy. Producing complex parts using the thickness inherent to blanking is much more restrictive than with PM.

7. Scrap Efficiency

If you’re an environmentalist, you’ll want to hide your eyes here.

Stamping processes always leave a web of unused material behind. On top of that, since the raw material comes in uniform width and thickness, it may not conform to the blank’s requirements. Your manufacturer even consumes material to clamp the sheet metal in the die!

Yes, you can recycle it, but stamping scrap only recoups a fraction of the original cost.

In contrast, material use in the powder metallurgy process is about 97%. If necessary, "green" compacts can be broken apart and reused. No wonder manufacturers call powder metallurgy a “green technology.”

Your Winner (Plus More Resources)

For thin metal parts from low carbon steel or nonferrous material, stamping is fast and cost-efficient. When appearance matters or the part needs special strength or magnetic properties, or complex features, powder metallurgy leads the pack.

It all comes down to the needs of your project. Are you OK with throwing away 50% of your material? Do you need a more daring design that improves magnetic performance?

While you’re pondering those possibilities, check out our free e-book below. It assesses the pros and cons of powder metallurgy vs. machining, stamping, casting, forging, MIM, and more. Don’t miss the chance to learn a new trick nobody’s taught you yet!