Some industries are constantly addressing the need for more speed, and electromagnetics is no different. Specifically, solenoid response time seems to be a sticking point for many design engineers.

Solenoids require high valve-switching speed to maintain precision and control. The magnetic flux inside takes a certain amount of time to reach its maximum after voltage is applied to the solenoid.

So, how can we address solenoid speed for the future?

In the Summer 2020 edition of our PM Component Spotlight, we look at the many benefits and uses for powder metallurgy (PM) in solenoid design. The solution involves some surprises along the way, including soft magnetic materials and high-temperature sintering.

(Note: This concept of that of a DC solenoid design. To learn about AC considerations, including AC solenoid design, click here.)

About Solenoid Design

A solenoid valve is electromechanically operated. Its job is to shut off, release, distribute, or combine fluids and gases in a wide variety of applications.

Solenoid valves are not all carbon copies of each other. Solenoid design varies by:

- The strength of the magnetic field they generate

- Electric current

- The mechanism they use to regulate the fluid/gas

- The type of fluid/gas they control

Solenoid Response Time: The Problem

No matter the type of solenoid you’re designing, your main complaint is probably the same as everyone else’s: “Why doesn’t the valve react fast enough?”

This is, of course, an issue because response impacts performance. If you want to close or open an exhaust gas recirculation (EGR) valve, for example, a poorly designed solenoid could:

- Hamper the engine’s performance

- Change pollution characteristics

- Create leakage

It’s also no small thing that most components of the valve must be compatible with the fluid or gas that will pass through it.

Whatever your situation, you may be tempted to sacrifice your other design criteria to improve solenoid speed. But what does that do to your end product?

Solenoid Response Time: The Solution

Powder metallurgy has a great reputation for solving material-related limitations. Here’s how your powder metallurgy manufacturer could solve the solenoid saga once and for all with material and process improvements.

Soft Magnetic Powder

Let’s start with the material. One of PM’s calling cards is that it allows for the use of unique soft magnetic material alloys. This material solution improves permeability and magnetic response.

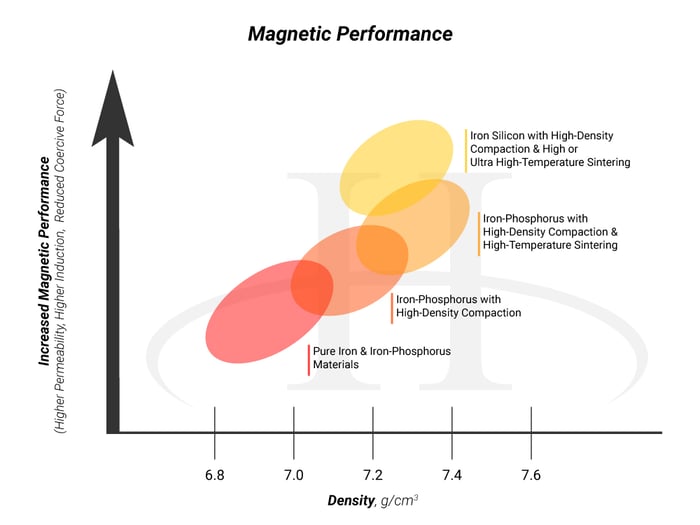

Pure iron, iron-phosphorus, and iron-silicon are the three options here.

Advanced Powder Metal Compaction

Many properties of a powder metal part are related to its density. Perhaps most notably, a denser part has:

- Greater magnetic qualities, creating a faster response time

- Less interconnected porosity, creating improved sealing

- Reduced tendency to deform

Improving the performance of a solenoid is more than just about density. The material selection, advanced powder compaction techniques, and custom sintering conditions all have parts to play. Only a select few powder metallurgy companies offer all of these services, so shop wisely.

Ultra-High-Temperature Sintering

Sintering has been used for many years to improve component strength. It’s also a great way to improve magnetic properties -- especially when you turn the heat up.

Many sintering furnaces around North America only reach temperatures of 2050°F for iron parts. However, new technology and techniques can bring the sintering temperature all the way up to 2500°F.

Sintering at these elevated temperatures opens opportunities to use other elements to improve performance. High-temp sintering forces grain growth in the material, resulting in stronger magnetic performance. High sintering temperature is especially important for silicon blends; otherwise they won’t fully diffuse into the base material. Full diffusion enhances magnetic performance and other key requirements of sintered metal. Meanwhile, better oxide reduction gives you stronger “necking” between each powder particle.

Think of it this way: Higher temperature = higher performance.

Solenoid Response Time: The Result

By using PM as your solenoid design guide, your product can exceed previous response times, and therefore perform more efficiently. But that’s not all -- the powder metallurgy process outlined above boosts strength and corrosion resistance too.

Sintered soft magnetic materials are excellent solutions for electrohydraulic control in automobiles, construction machines, and other applications. Along with these application-specific improvements, powder metal adds shape-making flexibility while reducing scrap waste.

What’s a More Rapid Response Than PM?

Powder metallurgy, when coupled with high sintering temperatures, deserves a serious look in solenoid applications.

Consider a switch to PM -- or upgrading your current powder metal part with ultra-high-temp sintering -- if you need a solenoid that has:

- Fast and safe switching

- Compact design

- High reliability

- Long cycle life

Check out our new ebook to learn more about how sintering can improve your part's performance!