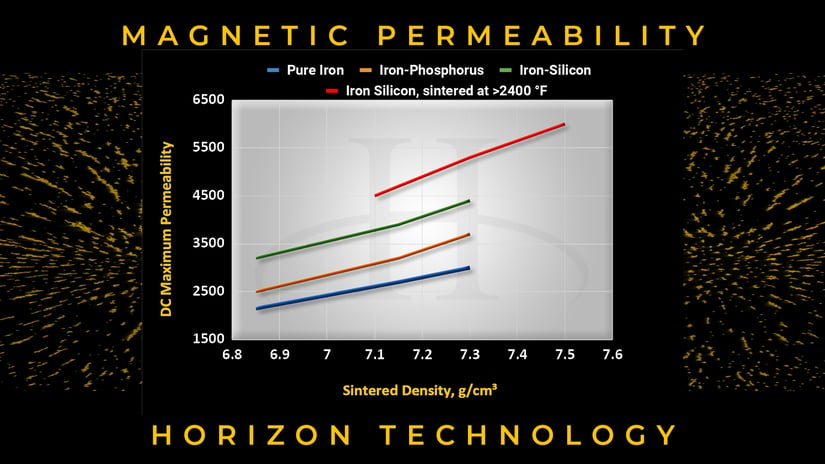

This article -- and this chart -- are a look at magnetic permeability. “Permeability” refers to how easily a material can be magnetized. If you’re having an issue getting a quick enough response to an applied current in your product, increasing the permeability is likely your answer.

Let’s look at how different tiers of advanced iron powder materials -- and the strong permeability of iron powder -- level up your component’s performance. Consider this a reminder that you can upgrade from your old standby material and get even better performance than you thought possible with powder metal!

Permeability of Iron Powders

The chart above shows the permeability of three sintered powder metal soft magnetic materials: Pure iron, iron-0.45% phosphorus, and iron-3% silicon. Both the iron-phosphorus and the iron-silicon were produced by adding either an iron-phosphorous or iron-silicon master alloy.

Alloying the iron with either phosphorus or silicon increases the permeability (how efficiently a material is magnetized by an applied current). Thus, if faster magnetic response -- for, say, a solenoid or an actuator -- there are three options:

-

Increasing density

-

Using phosphorus or silicon alloying systems

-

Merging #1 and #2 together

A great example of this is structural powder metals, where you need strength and temperature resistance and lubricity. By taking Door No. 3 above, you can get the synergy of both effects.

(DYK? Induction -- when magnetism is produced via the subject’s exposure to a magnetic field -- is merely a function of density. Higher density = higher induction.)

About These Types of Iron Powder ...

The three ferritic metal powders are represented on this line chart provide a good point of reference for using iron-based metal powder. Here’s the speed dating version of each variety. (Of course, there are other advanced PM materials out there, too.)

RELATED: Expanded flow chart of powder metal materials

Pure Iron

Pure iron, represented by the blue line, is the basis for most mixes of low-alloyed sintered steels.

High-purity iron has good soft magnetic qualities. A vendor can use coated or insulated iron to add new design options -- just keep in mind that resistivity in pure iron is quite low.

Iron-Phosphorus

Iron phosphorus, depicted as the orange line, boasts high:

-

Induction

-

Strength

-

Hardness

-

Ductility

The resistivity of iron-phosphorus is better than that of pure iron, but still not optimal if that’s a big concern of yours.

Iron-Silicon

Iron-silicon, the black line on the chart, has the highest maximum permeability of these three options.

Iron-silicon sintered parts respond better to moderate frequencies than their iron-phosphorus counterparts. It’s also favored for its solid impact resistance.

Sintering Iron

A brief word about the sintering of the three materials on this chart:

Both pure iron and iron-phosphorus powder can be sintered at a “normal” sintering temperature of 2050 degrees F. However, iron-silicon powder requires a minimum sintering temperature of 2300 degrees to fully realize the benefits of added silicon:

-

Full homogenization/uniformity

-

Increased density

-

Optimal magnetic response

Temperatures above 2300 degrees F will produce even better magnetic results. This advanced technology is only available at a select few powder metal parts manufacturers.

Outside the Box Isn’t a Bad Thing

The same performance analogy can be drawn not only from magnetic response, but also any other mechanical property. Remember, you can choose a better alloy, you can choose to bump up density, or you can choose both. And you can subsequently add in other characteristics by including other elements (lubrication, etc.).

Don’t let your mind get stuck on the MPIF Standard 35 materials. The box is the MPIF Standard 35. Thinking out of the box can improve your part's performance. All it takes is the courage to do powder metal differently.