Sintering is a powder metallurgy processing step with plenty of untapped potential.

We’ve previously discussed how high-temperature sintering can take your DC electromagnetic component’s properties to a level conventional sintering can’t match. Through recent advances in powder metallurgy -- like ultra-high-temperature sintering (UHTS) -- an even greater leap forward is possible:

- Solenoid designs with improved rapid-response time

- Permanent magnet rotor designs with higher strength

- Permanent magnet stators with higher magnetic saturation & permeability

- Other DC electric motor designs

Where Do Conventional Sintered Powder Metal Processes Fall Short?

Of course, we can’t tout the greatness of ultra-high-temperature sintering without first explaining the conventional sintering process at standard temperatures. If you’re already familiar with sintering, skip to the next section!

During the sintered powder metal process, particles fuse into either a solid or porous body (sintered neck formation) at a temperature below the melting point of the powder's dominant element.

Think of sintering as similar to ice cubes melting together in a glass of water. The longer the ice sits in the water, the harder it is to break those cubes apart.

An advantage of sintering is that it enables alloying additions to either completely or partially diffused into the base material and enhance strength or other key requirements of a sintered metal.

(Video courtesy Harb Nayar of TAT Technology)

Let’s focus on sintering metal parts made from soft magnetic iron powder. The objectives are:

- Remove the lubricant from the powder compact

- Reduce the oxygen content on the surface of the powder.

- Create sintered necks between adjacent powder particles

- Fully or partially diffuse added elements such as graphite, nickel, copper, etc.

The typical sintering temperature for iron powder is 2050° F for 10-60 minutes.

Adding graphite is a good example of the need to diffuse and homogenize an additive to the powder. Most commonly, die-pressed ferrous powders are produced with almost no combined carbon. Alloyed carbon reduces compressibility, limiting the potential density (which impacts both magnetic and mechanical performance, as you'll learn below)..

However, a carbon-free part will not have the strength required for many applications. So, graphite is added to the powder mix.

Copper is another elemental alloy used in many PM parts, for much of the same reason. Unfortunately, once initial diffusion happens, the subsequent diffusion of the copper slows down. Other elements (see: nickel) will only partially diffuse because they have a higher melting point.

Yes, you can prealloy these elements, but there are trade-offs and limitations to consider, including density and alloy selection.

Advances in Powder Metallurgy: High-Temperature Sintering

More than 90% of all powder metal parts are sintered at 2050 F°. Examining the types of sintering in powder metallurgy beyond the norm shows potential for increased diffusion of atoms across particle interfaces. This results in greater sinter neck formation and more pore rounding. Additionally, the homogenization of the elemental alloy additions is enhanced, giving the potential for higher performance.

Both of these concepts imply greater mechanical or DC magnetic properties in parts made from sintered soft magnetic materials. High-temp sintering also allows for the use of more innovative powder metal materials. We call these sintered soft magnetic materials (SSMs), and they're growing in notoriety for:

- Better hardness

- Potentially lower raw material cost

- … at the same (or even higher) level of mechanical & magnetic properties!

Ultra-High-Temperature Sintering

Ultra-high-temperature sintering (UHTS) is defined as sintering ferrous powder at temperatures approaching 2500° F.

The benefits of high-temperature sintering are augmented with UHTS. Sintered neck formation and alloy homogenization get a big boost from this new processing technique. Also, use of powder additions is expanded -- even ones not normally associated with conventional ferrous PM -- for even greater property improvements.

Recently, Horizon Technology has collaboratively developed the technology to sinter iron powder parts at UHTS. What does this do that conventional high-temperature sintering does not? Ultra-high-temperature sintering gives even more flexibility in alloy design for unique project requirements.

Improving Magnetic Properties

Properties of sintered soft magnetic materials are meant to balance mechanical and magnetic performance.

This advanced heat treatment process allows for:

This advanced heat treatment process allows for:

- Use of high-magnetic-permeability metal alloys (nickel, silicon steel)

- Increasing the sintering temperature of iron, nickel, stainless steel, etc. for improved saturation induction (flux density)

- Improved DC motor speed control

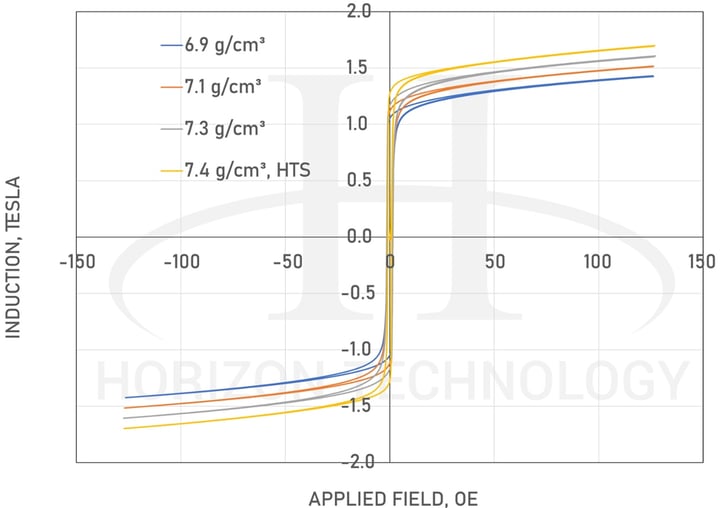

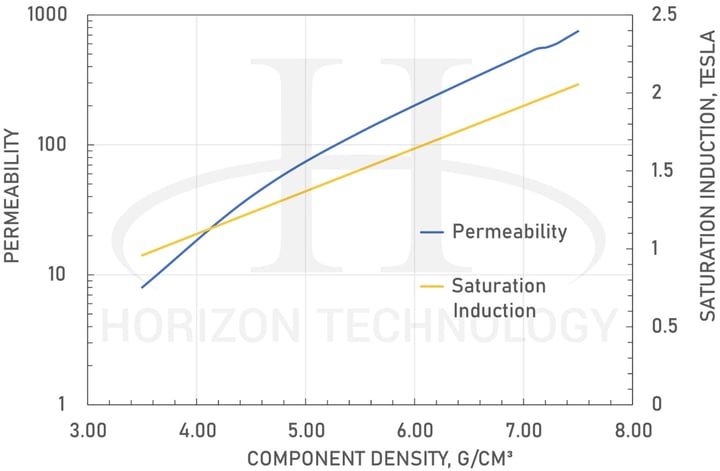

Response time is often related to magnetic permeability -- the higher the permeability, the quicker the response time. Moving from pure iron to iron-phosphorus – or, even better, to iron-silicon – increases permeability and density.

Why would you care about high density? For several reasons, but for the purpose of magnetic performance, know that one advantage of relates back to maximum induction.

A lower-density powder metal part may seem to offer the necessary performance, but there may be flux leaks because of the strong magnets used. Capturing that excess flux often requires adding a second part or adding mass to your existing part. Switching to a material and process that promotes higher density may allow you to reduce a two-part assembly to one.

Improving Mechanical Properties of Soft Magnetic Materials

Not only can you have a combo of prealloyed materials with elemental additions, you also get significantly enhanced atomic diffusion and homogenization. With greater pore rounding, this technology promises greater static and dynamic properties such as:

- Tensile strength

- Fatigue resistance

- Impact strength

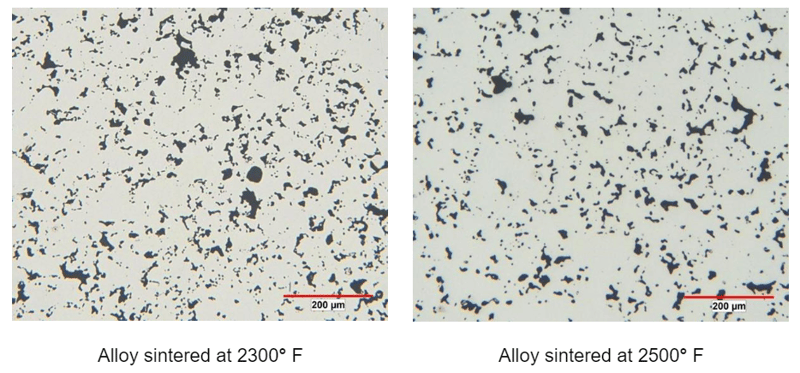

Let’s take a look at the pore-rounding effect of UHTS. Above are unetched photomicrographs of a proprietary alloy developed by Horizon, sintered at 2300° F (left) and 2500° F (right). The sintered densities of both samples were approximately the same (7.1 g/cm³). However, on the left you see a large number of fine pores more or less outlining the prior particle boundaries. On the right, the outlining of the prior particle boundaries is reduced and the appearance of the porosity is more rounded and the number of fine pores is reduced.

Let’s take a look at the pore-rounding effect of UHTS. Above are unetched photomicrographs of a proprietary alloy developed by Horizon, sintered at 2300° F (left) and 2500° F (right). The sintered densities of both samples were approximately the same (7.1 g/cm³). However, on the left you see a large number of fine pores more or less outlining the prior particle boundaries. On the right, the outlining of the prior particle boundaries is reduced and the appearance of the porosity is more rounded and the number of fine pores is reduced.

What does this mean for the mechanical properties of UHTS vs. conventional high-temperature sintering?

(Related Article: Design-for-Manufacturability Considerations - Sintered Soft Magnetics)

Mechanical Properties of Soft Magnetic Materials: 2300 °F vs. UHTS

The currently accepted heat treatment process for ferrous metals depends on the grade:

|

Material |

Alloy |

Heat Treatment |

Density, g/cm³ |

Trans. Rupture Strength, psi |

Yield Strength, psi |

Tensile Strength, psi |

Elongation |

|

FC-0208 |

Iron-Copper-Carbon |

Conventional sintered |

7.2 |

155,000 |

65,000 |

75,000 |

<1% |

|

FC-0208 |

Iron-Copper-Carbon |

Conventional sintered & heat-treated |

7.2 |

150,000- |

No defined yield point |

105,000 |

<1% |

|

FN-0205 |

Iron-Nickel-Carbon |

Conventional sintered & heat-treated |

7.1 |

185,000 |

130,000 |

145,000 |

<1% |

| FLN2-4405 | Iron-Molybdenum-Nickel-Carbon |

Sintered at 2300 °F |

7.1 |

305,000 |

125,000 |

162,000 |

1.5% |

|

FLN2-4405 |

Iron-Molybdenum-Nickel-Carbon |

Sintered at 2500 °F |

7.1 |

350,000 |

185,000 |

215,000 |

1.7% |

The ultimate tensile strength increased from 162,000 psi to ~215,000 psi. Equally important is the improved elongation characteristics in the UHTS samples. Elongation is a good measure of damage tolerance. Both samples showed metallographic analysis of nearly 100% tempered martensite.

If we refer to MPIF Standard 35 for powder material standards, this combination of properties is not available in any of the listed materials (at a sintered density of 7.1 g/cm³).

Yes, a 4% nickel steel with 0.5% graphite and 0.85% molybdenum will give higher strength. But this material was also sintered at 2300° and evaluated at a minimum density of 7.3 g/cm³. It showed elongation of 1% or less.

The damage tolerance of this material will be less than the UHTS material.

More on the Sintered Powder Metal Process ...

Even more breakthroughs are coming in ultra-high-temp sintering and soft magnetic materials as we speak:

- Advanced compaction technology

- New alloy compositions

- Sintering process improvements

These adjustments will further improve sintered density, magnetic saturation, and mechanical properties in electrical machines. More importantly, they'll bring new performance characteristics -- and efficiency -- to DC electric motors, rotors, and stators.

The industry also must investigate specialized heat treatment of metals and alloys, such as carburizing and carbo-nitriding. Expect these specialized processes to upgrade the overall performance possible with ultra-high-temp sintering.

These developments are ongoing and will be documented in future blogs. We expect great things from this research and look forward to working with powder metal parts users to exploit this technology!

Thanks to Hoeganaes Corp. for its assistance in the physical testing and metallographic analysis

(Editor's note: This article was originally published in August 2019 and was recently updated.)