Whether you're new to the world of powder metallurgy design or want to take your current component to the next level, you’re going to need help. Since powder metal is such a niche industry, finding the information you need on materials and processes can range from a hassle to downright impossible.

Fortunately, there is one major resource new and experienced engineers can rely on -- the MPIF Standard 35 material guidelines. But the rules of powder metallurgy don’t start and end with the Standard 35 -- your design considerations may call for something a little more innovative.

The following is everything you should know about the MPIF’s Standard 35 materials for powder metallurgy. And for the more ambitious, we’ll also reveal some advanced material and process considerations that may help you outdo your competitors.

The ‘Rules’ of Powder Metallurgy: MPIF Standard 35 Overview

The Metal Powder Industries Federation created the MPIF Standard 35 to present and clarify powder metallurgy (PM) technology and capabilities. The goal of the guidelines is to provide a common performance language between PM parts producers and end users. You can also use them to gauge the disadvantages and advantages of powder metallurgy vs. casting, forging, and other metal forming processes.

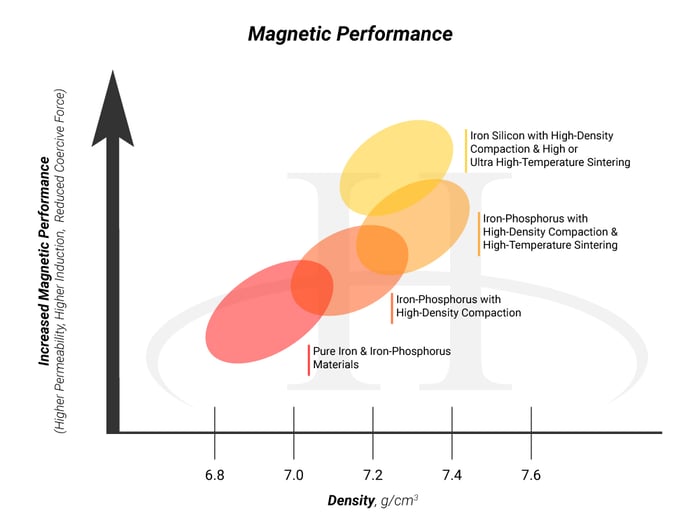

The MPIF’s intention is to be a single, credible source to help people understand the mechanical properties of powder metal materials. This means not only as a function of chemistry, but also density and thermal processes. It's also a resource to help newcomers to the industry become acquainted with common powder metallurgy terms and properties.

Updated every 3-4 years, MPIF standards books come in a few varieties. The, uhh … “standard” Standard 35 focuses on structural powder metal materials. Other, separate handbooks are geared toward bearings and powder forgings.

Benefits of Leaning on the MPIF Standard 35

There are many benefits to using the Standard 35 materials as a go-to, especially for engineers new to powder metallurgy The biggest boon is that it can help you better understand what different types of powder metal can do for your component, and help you communicate this to your engineering team. You can use the search function on the Standard 35 site to define the properties and performance that you're looking for in powder metal, and then quickly access the material options and processing types that might be best for your application. Before the Standard 35, there wasn't really a good way to communicate PM’s performance abilities to designers.

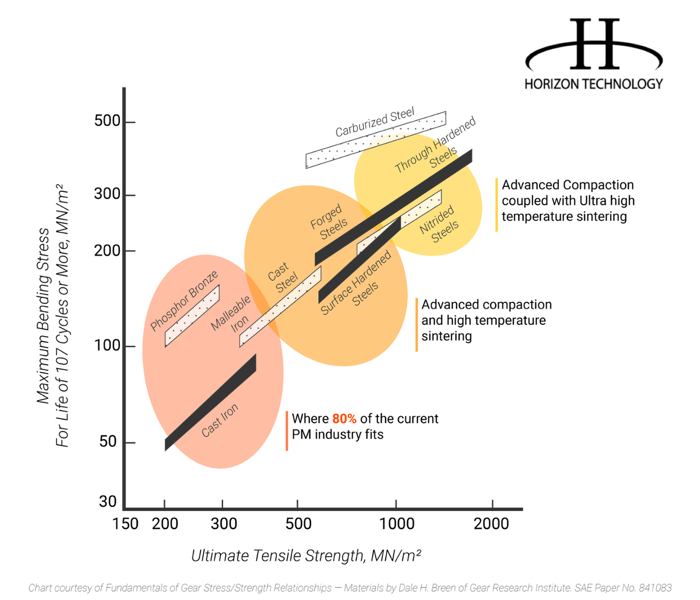

These materials are called the Standard 35 for a reason -- they’re only a starting point. In fact, there's a saying that claims "80% of the PM industry is where the Standard 35 lives." (OK, we made that up ourselves.)

Iron-copper-carbon (ICC) is an example of a highly popular material that's a good starting point for PM. But what’s popular is not always right, especially when it comes to advanced electromagnetic and structural PM applications:

Advanced Materials for Consideration

Have a project and don't think the Standard 35 can give you the properties that you're looking for in your motor or similar application? Consider looking into materials and processes that are more advanced than the Standard 35.

Here's a look at three that might be ideal for your next project:

Soft Magnetic Composite

Increasingly common in automotive applications, these materials improve magnetic performance, while being more compact and dense. Soft magnetic composites feature a layer of electric insulating film coating and have high electrical resistivity.

Sintered Soft Magnetic Material

Ideal for parts like solenoids, rotors, stators, and other DC applications, sintered soft magnetic materials allow product developers to combine magnetic performance with the improved part strength that sintering affords. When you use sintering, you also have the option to create alloy materials, something that isn't currently possible with soft magnetic composite.

Ultra-High Temperature Sintering

This isn't a material so much as it is an alternative process that takes heat treatment to the extreme.

Ultra-high temperature sintering uses temperatures approaching 2500° F, several hundred degrees hotter than conventional sintering. The extra heat creates parts with greater fatigue resistance and tensile strength, once a sticking point for PM naysayers. It also allows more flexibility in overall design and optimizes mechanical properties to right where you want them in relation to cost.

Consider ultra-high-temp sintering as a potential step up from even high-temperature sintering.

If You Still Can’t Find a Match

The MPIF Standard 35 is a great starting point -- just don’t make it your stopping point.

If you can’t find what you're looking for in the Standard 35, check out the alternative materials or processes we outlined above. If you’re still stuck, contact a powder metallurgy expert to get a more specific recommendation that meets your budget.

For more information on design considerations for powder metallurgy that can be solved specifically by soft magnetic composite, check out the free e-book below: