There’s no question soft magnetic composites (SMCs) hold many benefits for electric motors, but one common concern we’ve seen is reduced permeability relative to steel laminations and how this will affect the performance of your electric motor.

What are the effects of permeability and should it be your only consideration?

What is Permeability?

Permeability is the property of ferro-magnetic materials that determines how easily the material is magnetized. Higher permeability implies the material magnetizes at a faster rate. This key characteristic of high permeability is often used in fast acting solenoids and relays to minimize response time.

Relative to electric motors, permeability relates to how quickly the motor can spool up to operating speed, or how much current is required to achieve any given magnetic induction (consequently torque in the motor).

Steel Laminations & SMCs: How Do They Stack Up?

Comparing the permeability response of steel laminations to SMC materials (see Figure 1 below), you’ll see that current SMC materials have a lower permeability relative to steel laminations.

.png?width=524&name=SMC%20vs%20Lamination%20BH%20Curve%20(1).png)

SMCs have reduced permeability for several reasons:

First, the individual iron particles in an SMC component are magnetically and electrically separated from one another. This inter-particle insulation prevents the easy transfer of magnetic flux from one particle to its adjacent neighbors, acting as a distributed air gap within the material; effectively lowering the permeability. While inter-particle insulation may be bad for permeability, it provides low core losses and reduced heat generation while maintaining a 3D flux path for the stator.

Second, during the manufacture of SMC components, insulated powders are compacted at high pressures to form the final 3D net shape. With current post-compaction curing conditions, the temperature is insufficient to anneal away the detrimental effect of cold working. Cold working also contributes to a reduction in the permeability of the material.

Looking at Figure 1, you can see that the higher permeable steel laminations show higher magnetic induction at relatively low levels of applied field (motor current). However, if the motor is operating at high levels of induction (greater than 1.7T), the difference in current applied versus measured induction is negligible. Depending on your motor configuration and materials used, SMCs offer better performance at higher induction levels.

Is High Permeability Necessary?

Looking at Figure 1, you’ll see that SMCs have lower permeability than standard laminations.

The largest consequences of reduced permeability with SMCs relates to the higher currents required at lower magnetic operating fields. This is usually only a minor issue, depending on what device you’re operating and where you’re operating it.

These deleterious effects are inherent in current state-of-the art SMC materials, however, for many applications, these aren’t show stoppers (especially for high speed/high frequency applications).

For high speed/high frequency applications, a major consideration is heat. SMCs generate less heat over laminations due to lower eddy current losses, leading to higher efficiencies and reducing the need for external cooling.

Can SMCs and Laminations Be Friends?

The negative effects of the distributed air gap and cold working (without magnetically annealing) make it easy to understand SMC materials will have lower permeability. But let’s explore some other issues influencing the operational performance of the motor.

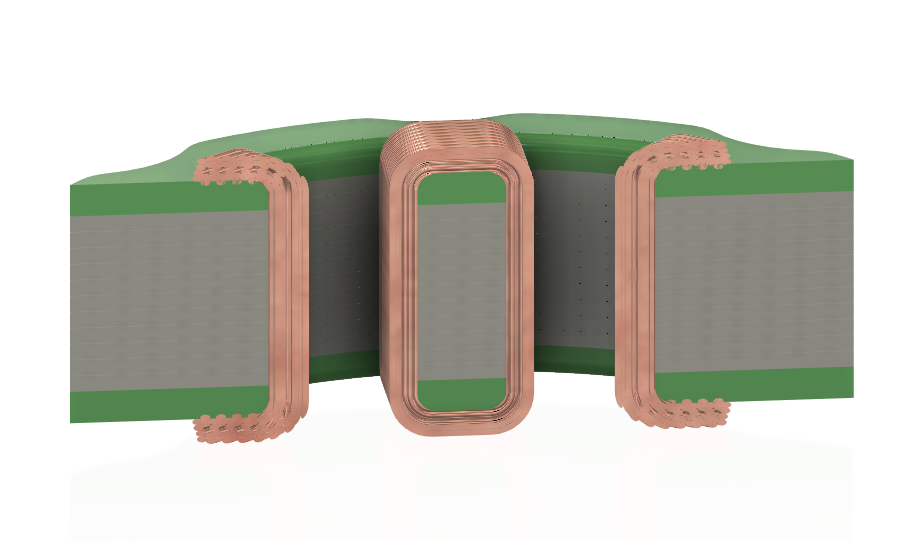

Are you looking for more efficiency, but know SMCs can’t be a drop in solution to your lamination design? Now there’s a way for you to marry these two technologies.

Consider a radial flux wheel motor that has the requirements of short stack length and high power. An inherent drawback of short stack length is the excessive end turn requirements to wind the motor. What if we could use magnetic material in the end turns to be part of the magnetic circuit? Enter SMCs, with its 3D manufacturing capability. Now, you can fill that air gap under the copper with magnetic material that can boost performance without changing your magnet material. A marriage of technological bliss.

So What’s on the Horizon for SMCs?

Pun intended...

We’ve already addressed the elephant in the room: permeability. However, how do we envision the next generation of SMC materials/processing?

What if the insulation can become less of an impediment and can be cured at higher annealing temperatures? This creates an SMC with higher permeability and even lower losses, opening the door to even more demanding applications.

To learn more about SMCs and electric motor design, check out our free e-book: “AC Electric Motor Design Guide: Soft Magnetic Composites.