Engineers, and probably purchasers too, have been comparing powder metallurgy with competing processes for a long, long time. As for powder metal parts vs. forged parts, just like any other comparison of manufacturing methods, it helps to know the benefits and potential drawbacks of each process.

Powder metallurgy (PM) offers a lot of advantages you should consider -- some obvious, some not so much. There are admittedly situations where forging might be the better option, too.

Let’s look at the ideal uses and applications for powder metal vs. forged parts:

Powder Metal Vs. Forged Parts

Since reaching the mainstream, powder metallurgy has become the obvious solution for producing small parts in many scenarios.

By this point, you could argue that many cast parts that could have been replaced by PM have been replaced. So what’s the next frontier in using powder metal to its fullest? What about forged parts?

The answer is very specific to your application.

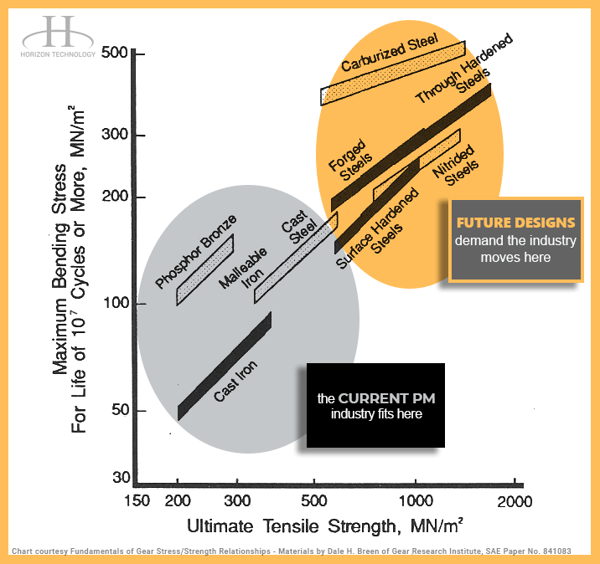

These charts show the relative performance of various wrought materials (of which forged parts are a subset) and then show where powder metal fits in the narrative. This sets the stage for where PM is now and, more importantly, where it could be.

Looking at cast iron, phosphor bronze, etc. -- this is where 80% of the powder metal industry lives today. But powder metal parts now easily outperform cast iron products.

As for the chart on the right? There are a new range of opportunities -- if this is where your component needs to fit, you can work in powder metal to achieve higher performance. Need strength? Hardness? PM can be your playground in the realm of structural materials.

In short, if you plan to design your component using typical iron-copper-carbon, powder metallurgy may not work for you. But if you examine more advanced materials and processes, PM may provide the performance you need at a cost much lower than forgings.

Let’s take a closer look at some of the advantages and disadvantages of powder metal and forged components:

Powdered Metal Parts

Advantages of Powder Metallurgy:

- Can produce parts from materials capable of high-temperature service and extreme durability at lower cost and at reduced difficulty. Think of stainless steels that are subject to high temperatures in exhaust systems, etc.

- Can maintain high production rates for parts, even complex parts.

- Machining is mostly unnecessary due to the net shaping capabilities of powder metallurgy. Less secondary machining means lower labor costs.

- High level of control is achievable using metal powders and sintering. This allows fine tuning of electrical and magnetic properties, density, damping, toughness, and hardness.

- High-temperature sintering offers substantial improvements in tensile strength, bending fatigue strength, and impact energy.

Disadvantages of Powder Metallurgy:

- There are often size limitations to PM parts that can make certain designs impossible to produce. The biggest presses in the industry are about 1,500 tons. This limits practical part size to about 40-50 sq. in. of planar area. More realistically, average press sizes are in the 500 ton range, so plan accordingly for your part development.

- Complex-shaped parts can also be challenging to make. However, high-skill metal parts manufacturers can get past this challenge, and even help you with your design.

- Parts are generally not as strong or as ductile as cast irons or forged parts.

Forged Metal Parts

Advantages of Forging:

- Alters the grain flow of the material so that it flows with the shape of the part.

- Creates parts that are stronger than other manufacturing processes. Forged parts are great for when failure would be dangerous or extremely inconvenient -- like gears in an automobile engine.

- Can be made into most shapes.

- Can create very large parts.

- Relatively inexpensive compared to machining.

Disadvantages of Forging:

- Lack of control over microstructure.

- Greater need for secondary machining, which adds to the project’s cost and lead time.

- Cannot produce porous bearings, sintered carbides, or parts with a mix of multiple metals.

- Cannot produce small, finely designed parts without machining

- Die production is expensive, making the economics of short production runs undesirable.

Where Does Your Project Fit In?

If you’re trying to weigh the advantages and disadvantages of forging versus powder metallurgy, it likely means you’re seeking a manufacturing process that offers an ideal cost-performance balance. The closer you look at each process, the more you’ll discover it depends on your project criteria.

Forging is better for some situations, while PM is better for others. It honestly depends on what you’re trying to accomplish.

Powder metallurgy has grown by leaps and bounds as technology and processes have advanced. We (both supplier and OEM) can do amazing things with powder metal now -- just look at what leading manufacturers are doing with high-temperature sintering. In some cases, simply raising the sintering temperature by 100° to 300° F can produce significantly better results in:

- Strength

- Impact energy

- Other factors (just ask us)

The experimentation with powder metal materials and processes is ongoing. It wouldn’t be surprising if more substantial improvements are made in 2020 and beyond that make PM even more competitive with competing manufacturing processes.

There are still some areas where forging is a better solution. No one will be producing steel I-beams via powder metal anytime soon, or a crowbar, for that matter. However, when it comes to smaller parts with intricate designs, forging has been eclipsed by PM. And as we move into the future of part production -- like for electric engines in ever-evolving automotive designs -- powder metallurgy will take on an increasingly important role.

When factors like affordability, high production runs, and unique metal combinations come into play, PM is clearly the future.

While forging can provide excellent mechanical properties, it comes at a significant cost penalty over conventional powder metal. With today’s advanced materials and processes conventional powder metal may provide the performance needed for your application and at a greatly reduced cost.

Your Source for Information on Powder Metallurgy

Got a passion for improving your design. It may be time to question whether powder metal materials and processes are better suited for your manufacturing needs.

Before you jump in, it’s best to discuss with a powder metal parts manufacturer the additional benefits and concerns of using PM for your next project.