Powder metallurgy has grown increasingly popular for the fabrication of complex-yet-reliable components. But what if we told you there was a nearly entirely different rulebook depending on the material you choose?

Let’s set aside structural applications and focus on powder metallurgy (PM) projects that require soft magnetic properties. Powder metal materials for these applications come in two categories: soft magnetic composites (SMCs), ideal for AC components, and sintered soft magnetic materials, better suited for DC parts.

In many AC electromagnetic applications (i.e. stators), SMCs can maximize magnetic performance while minimizing energy use. Specifically, they can outperform electrical steel laminations at frequencies as low as 60 Hz -- if you’ve got the knowhow and the right manufacturer.

This guide will specifically cover powder metallurgy design considerations for SMC-needy applications.

If your project doesn’t fall into that category, visit our DFM articles addressing other PM applications:

SMC Performance Trait Audit

A Brief Intro to SMCs for Powder Metal Parts

While some design principles outlined in this guide may apply to other powder metal parts, or even stamped laminations, you can’t as easily prototype or machine soft magnetic composites. When it comes to PM, what’s possible with a structural component may be illogical for an SMC part.

An experienced manufacturer can help you leverage the advantages of powder metallurgy and work within its complexities. But by understanding how each production stage affects the magnetic and mechanical properties of parts made by powder metallurgy, you can help your manufacturer help you.

Let’s begin!

Why Design Powder Metal Parts for Manufacturability?

Design for manufacturability, or design for manufacturing (DFM), is a key engineering philosophy that emphasizes practical limitations from the very beginning of the design process. Failing to design for manufacturing can cause major disruptions later in production.

For instance, upon entering production, an OEM may learn that its component is inefficient to make because of unnecessarily complicated design or extremely tight tolerance specs, leading to ballooning production costs. Even worse, failing to account for the complexities of manufacturing can mean that fatal design flaws go unnoticed until production begins.

This is true in powder metallurgy, just as it is in other manufacturing processes. In conventional powder metal, we focus on:

- Strength

- Hardness

- Elongation

- Fatigue

But when you develop an SMC part, you need to understand:

- Frequency

- Material choices

- Core losses

- Permeability

- Assembly needs

- Tolerances

- Avoiding sharp edges in wire winding locations

If you fully understand the capabilities of powder metallurgy and SMCs (or work with a vendor who does), your design can reach its full potential.

Just because you have a powder metal parts supplier doesn’t mean you have one qualified to design and manufacture SMC parts. There are very unique requirements vs. “conventional” powder metal:

Key Design Considerations for Soft Magnetic Composite Parts

Applying the DFM principles to the development of SMC parts reveals four major design considerations for powder metallurgy. These include the part's size and shape, as well as any unique features of the component's geometry.

Part Size

Part size is one of the fundamental design considerations as you figure out your manufacturing path forward.

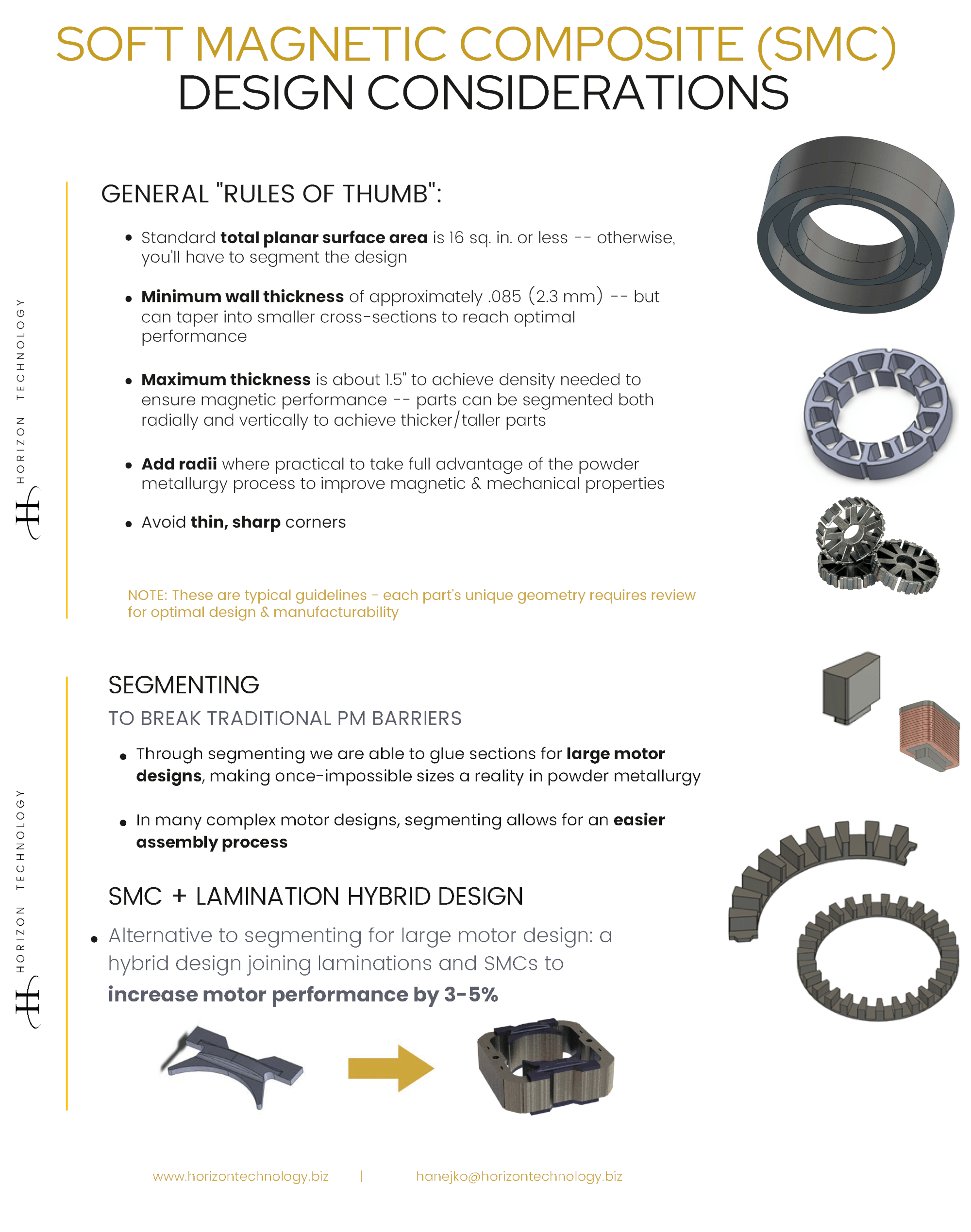

The planar surface (the surface area of a cross-section of the component) is the most important measurement here. As it stands now, parts requiring a planar surface over 16 sq. in. are typically segmented into multiple components, while smaller parts can be manufactured in one piece.

Key words being, “as it stands now.”

PM also comes with other dimensional requirements, although these depend heavily on the individual part. In general, SMC parts should have a minimum length of 0.06", or 1.725 mm, in the pressing direction. Also, it can be difficult to form parts with a length exceeding 2" in the pressing direction.

Despite these general guidelines, it's important to remember that the rules of powder metallurgy design are made to be broken. The most capable powder metallurgy companies are willing to consider minimum and maximum sizes on a part-to-part basis, since the rest of the part’s geometry has such a major impact on manufacturability. When in doubt, consult your vendor to see what's possible relative to your performance and size requirements.

Part Shape and Complexity

Part shape goes hand-in-hand with size, but it also brings its own constraints -- or, should we say, possibilities?

Admittedly, SMC parts don't hold up well to secondary machining because cutting and even just fixturing the part can damage or break it. Because of this limitation, engineers should carefully consider whether PM can accommodate their part's geometry with minimal finishing processes.

In general, powder metallurgy’s “additive” nature can easily accommodate complex designs with multiple levels.

SMCs, in particular, use a 3D flux path that eliminates the orientation constraints that would come with stamped laminations. However, there's a fine balance between leveraging PM's full flexibility and over-engineering, which can complicate production.

We can help you determine whether a part is within PM's capabilities or whether it would be better to split into multiple components. Fortunately, powder metallurgy parts can easily be joined with the appropriate epoxy, so segmenting is often a viable option. A skilled manufacturer can even combine dissimilar materials or even dissimilar processes (like an SMC + lamination hybrid assembly).

Wall Thickness

Along with size, shape, and application-specific requirements such as frequency, wall thickness is another core consideration for SMC parts. Powder metallurgy processes typically include a 0.06" minimum thickness for both inner and outer diameters.

However, depending again on the part geometry, some walls can taper into smaller cross-sections. For instance, the tips of stator teeth are often 0.06" thick on their own, but can taper down further if the application calls for it.

When considering a thinner cross-section, engineers should bear in mind that reducing the thickness increases fragility. Again, if you’re working with lower-frequency materials, 0.06” may be unrealistic.

Since the rules of powder metallurgy change based on product requirements, consult an expert if you have a special size or shape need.

Special Features

Finally, if a part calls for special features, consult with an experienced vendor to determine whether PM can accommodate them. Examples include:

- Cross-holes

- Undercuts

- Flanges

- Grooves

While most of these features are machined when using conventional powder metal, the current state of SMC materials doesn’t allow for cross-holes and undercuts. However, ongoing advances in material and pressing technology may make them possible.

Your powder metallurgy company should work with you to develop a custom solution, which may involve borrowing from the best of several options. Remember, powder metallurgy isn't just flexible in its shaping ability -- it also lets you join dissimilar metals or processes, such an SMC-lamination hybrid design.

Working With Outside Engineering on Your Powder Metal Part

Designing for manufacturability isn’t easy, no matter how you make your part. In powder metallurgy, DFM requires a firm understanding and communication of both your own requirements and PM's capabilities.

To prevent delays, engineers should work closely with their vendors early and often in the design process to optimize their part long before production begins. Fortunately, when done right, DFM yields soft magnetic parts that outperform components from any comparable manufacturing method, so the effort’s well worth it.

Still need guidance optimizing your part for magnetic performance? Contact us and check out our resource page for soft magnetics and electromechanical design: