The common consumer wants a car that will get them from point A to point B without any added hassle or distraction. Electric vehicles improve driver experience by reducing NVH (noise, vibration, and harshness).

Traditional internal combustion engine vehicles suffer from NVH a lot more than electric vehicles do, which impacts driver quality-of-life.

In this post we’ll break down how electric motor NVH improves the user experience and how soft magnetic composites can optimize electric motor performance and even lower NVH.

Most Efficient Electric Motor Design for Low NVH

If we’re going to focus on electrification, the classic feature of an electric motor is almost zero NVH. The most sound you’ll get is minimal gear whine.

NVH in electric motors is a negligible factor because:

- Rotation is limited to a central axis, limiting motor and powertrain vibration

- Electric motors are typically more compact

- EVs require less energy to move because electric motors generate instantaneous max torque so you eliminate the need to rev the engine.

But how are electric motors able to provide these benefits while remaining cost effective and efficient? SMC is your answer.

SMCs for Automotive Powertrain Design

Manufacturers of automotive electrical components have been using steel laminations for a long time, but that method is restrictive in a few ways.

Parts made with laminations are noisier because of the effect the vibrations have on the lamination stack. Think of thumbing through 100 pieces of paper versus one piece -- single component made with SMC material.

Because of the inherent shape-making capabilities of powder metal, SMC materials allow manufacturers to take advantage of complex geometries. Stators, for example, can be made more effectively with PM methods, and SMC materials can boost their magnetic performance.

EV Powertrain Design vs. ICE Powertrain Design

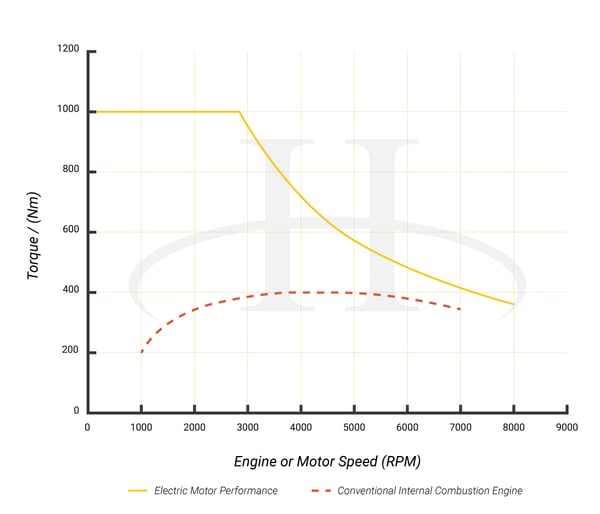

The old saying was, “You drive torque to 100 mph, but drive horsepower above 100 mph.” Those numbers probably aren’t exactly on-target, but the trend is still the same.

The above chart shows us that EVs create instantaneous max torque while internal combustion vehicles take time to rev up to maximum horsepower, creating additional NVH.

For combustion engine vehicles, there’s a correlation between high speeds, efficiency, and NVH. As speed increases, efficiency decreases and NVH rises. Electric vehicles experience a similar decrease in efficiency -- only at very high speeds -- but without the increase in NVH.

At the end of the day, creating a more efficient electric motor at a lower cost will improve the driver experience, and the use of the SMC material will help extend the range of the electric vehicle.

Powder Metal + Electric Motors = Low NVH, High Efficiency

Powder metal and SMC materials can create lighter components with improved magnetic performance that not only make electric motors more efficient, but also reduce noise, vibration, and harshness.

To learn more about the potential of SMCs and powder metallurgy for electric motor technology, check out our Engineer’s Hub for Electric Motors.

If you liked this article, keep an eye out for our upcoming article about how SMCs can improve more than just EV drivetrains.