We're not satisfied with the status quo, and you shouldn’t be either. To give your powder metallurgy component better strength, magnetic qualities, and cost-efficiency, we push the boundaries of existing technology to surpass industry standards.

That’s how we make your metal powder products a success. To learn more, visit our Resources page for information on powder metallurgy’s advanced materials, capabilities, and applications vs. competing processes like forging and casting:

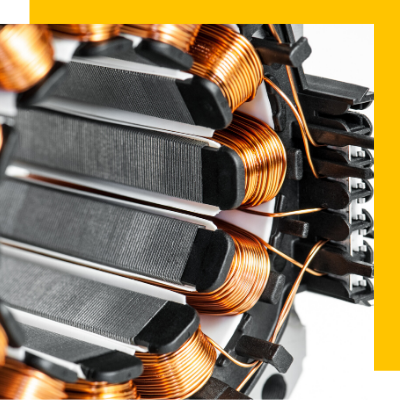

A tenant of the electric vehicle is to reduce waste and energy expenditure. That’s why considering powder metal parts for your motors is crucial. PM produces less waste than die casting or machining and is suited for crafting complex shapes impossible with many competing methods.

Led by industry experts, our processes cut costs, ensure structural and magnetic performance, and reduce waste. We take the use of powder metallurgy in AC and DC motor design and manufacturing seriously, which is why we’ve compiled a resource hub for increasing electric motor efficiency.

Interested in making a better electric motor? Learn more about all the benefits of powder metal parts at our Engineering Hub.

Horizon leads the way on several material and process advances that give our customers unique advantages in design of electric motors, solenoids, and high-strength structural applications.

Top-shelf magnetic performance in a 3D design that reduces core losses, material use, and weight for AC products.

For DC applications requiring rapid response and high magnetic performance, plus higher strength if necessary.

Take your component’s strength and ductility to a level conventional powder metal can’t match -- but only at Horizon.

The Horizon Technology mission is to demonstrate the versatility of powder metal components in a variety of applications -- not just the auto industry! PM is a green technology with few limits besides your imagination.

We aim to not only make powder metal manufacturing a low-cost alternative, but also the go-to for greater component performance.

We’re capable of serving any industry that requires a solution for small metal parts manufacturing that’s either higher-performing or more cost-effective -- or both.

Our customers fall into two groups. If your current part is falling behind the pack, we can improve its performance or cut your costs with powder metallurgy (PM).

If you’re already using powder metallurgy but want to take your component to another level, we can facilitate 3D design and unmatched total component performance, whether your needs are magnetic or structural. To explore your options in more detail, download this complimentary PDF:

Contact Horizon Technology today to see how our self-developed advances in powder metal manufacturing can get results for you:

Your powder metal component may be a perfect fit for our capabilities, but there's only one way to find out...

Please fill out the form to receive your quote. We'll be in touch soon!

People. Passion. Powdered Metal.

293 Battery Street

St. Marys, PA 15857

(814) 834-4004